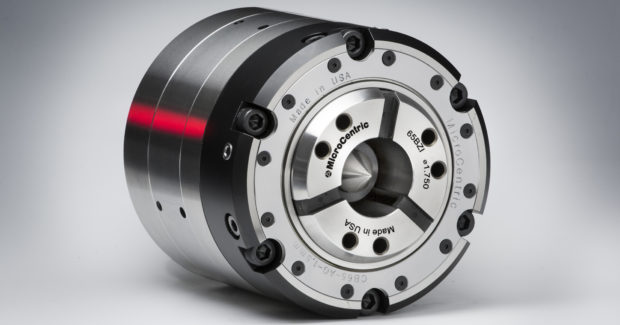

Quick-Change Compensating Collet Chuck

Featuring a compact outer diameter and shorter than conventional compensating chucks, MicroCentric’s chuck has a collet with a floating seat that enables the holder to compensate up to 0.060-inch (1.5 mm).

Posted: July 22, 2020

MicroCentric Corp. (Plainview, NY) designed the quick-change compensating collet chuck for applications where shafts are machined between centers.

The chuck’s pullback design features a floating collet seat and incorporates a mounting in the ID of the chuck body for centers or other types of locators. The floating seat enables the quick-change collet to compensate up to 0.060-inch (1.5 mm). Featuring a compact OD and shorter than conventional compensating chucks, the quick-change compensating collet chuck provides greater rigidity and tool clearance.

All components are made from hardened alloy steel precision-ground for the highest accuracy and long-term performance. The collet seat is sealed and the chuck is lubricated for life, requiring minimal maintenance.

The chuck generates a maximum clamping force of 18,884 pounds (84 kN) and is rated for spindle speeds up to 6,000 rpm.