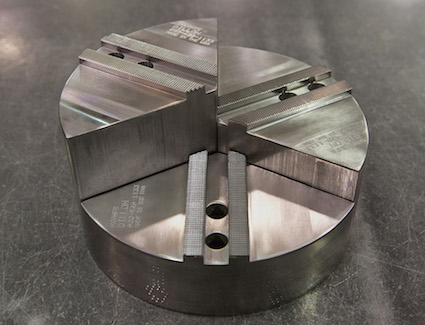

Custom Full-Grip Jaws Securely Grip the Workpiece

Special pie jaws from Dillon Manufacturing are designed to reduce part distortion by distributing gripping pressure across the workpiece. Customized to your specs for height, diameters, materials and configuration, they’re offered in a choice of four serrated designs.

Posted: July 1, 2020

Dillon Manufacturing’s (Springfield, OH) custom full-grip jaws with special heights, diameters, materials, and configuration securely grip any workpiece. They can provide a matching serration location that is exactly perpendicular to the slots and a solid gripping surface to provide more friction for drive with reduced distortion.

These special pie jaws can reduce and simplify set-up times, and that enhances project profitability. Custom full-grip chuck jaws are made in the U.S. with industry-leading lead-times. They are available in A356 aluminum, 6061 aluminum, 1018 steel and cast iron. This latest workholding introduction complements Dillon’s broad line of standard full-grip pie jaws, making them ideal for high speed machining, as well as precision boring, tapping, drilling and finishing across virtually all industrial markets.

These wrap-around type top jaws distribute more of the gripping pressure across the workpiece, reducing part distortion. Dillon custom full-grip jaws are available in serrated, tongue & groove serrated, Acme serrated, and square serrated designs.