Comparing Methods for Welding Preheat

Heating the base metal adds time and money up front, but can save time and money by minimizing potential for weld failure. Here’s how to determine the best preheating method – convection ovens, induction, open flame, or resistance heating – for your application.

Posted: July 24, 2020

MELTING POINT COLUMN

BY NICK PETERSON

Welding preheat is important in many applications. It’s used to help ensure weld quality and reduce cracking and other problems that can result in costly rework.

Preheating is often required in shop and field welding for oil and gas transmission pipelines, power plants, structural steel construction, mining, shipbuilding, and heavy equipment applications.

When welding applications require preheat, choosing the right method can save money, improve safety and boost productivity. Selecting which type of heating process you need is the first step; the next is choosing heating tools that are compatible with your applications.

When To Use Preheat

Preheating involves heating the weld joint and the area around it or the entire part to a specified temperature before welding. This reduces the residual stresses and cooling rate of the weld and drives out moisture, which in turn helps prevent hydrogen buildup and the potential for cracking.

Determining if an application requires preheat depends on several factors, including the type and thickness of your base material. It’s typically dictated by the welding code being used.

To meet code requirements, the welding procedure specification (WPS) for the job will outline the minimum and maximum preheat temperatures as well as the necessary duration of preheating. Often, a part must be held within a specific temperature range for a certain amount of time — such as between 250 degrees F and 400 degrees F for 30 minutes — before welding can start.

Several methods can be used for welding preheat, including induction, open flame, resistance heating, and convection ovens. The best preheating method for a specific application often depends on the material thickness, the size and quality of the weldment, the project timeline and budget, and available personnel and expertise.

The Four Common Preheating Methods

In welding preheat, the heat can be applied around the area of the weld joint or the entire part can be heated. There are four common preheat methods:

Open flame. Operators mix fuel gas with oxygen in a torch with a large heating tip, typically called a rosebud, and apply flame directly to the part. This process is often used for convenience; if operations already have a torch, additional equipment doesn’t need to be purchased for preheating.

The process is inefficient, though, so it can result in inconsistent temperature uniformity with temperature stick verification, poor mechanical property of the weld, and a slower time to get the part to temperature. There are also comfort and safety issues for operators while using an open flame and working near the soot, smoke, and gases produced with this method.

Resistance heating. Electrically heated ceramic pads, or tile, placed on the base metal transfer heat to the part through radiant and conductive heat where the pads are in contact with the part.

The process can deliver temperature consistency if the system is working accurately and no pads are broken. It can be used for larger projects and parts and often for stress relieving (post-weld heat treatment) processes.

However, cost can be higher because the process is often contracted to a third party who controls the schedule. It can also be time-consuming — sometimes taking an hour or more to arrange and secure the heating pads to the part — and the required cool-down time adds to the time for setup and removal.

Resistance heating elements also need insulation to help retain heat. The insulation and ceramic heating pads are costly consumables that occasionally need to be replaced, and the work environment can be an issue for these fragile components. Broken pads can cause hot and cold spots in the part. In addition, resistance heating elements get extremely hot and can pose a safety hazard for operators.

Convection ovens. Uniform heating is possible because the entire part is placed inside an oven. It’s also a good option when a large part must be heated, or when the operation must batch-heat many parts at once.

However, because ovens can be large and require connection to an electrical outlet, they’re often permanently installed in one location. Parts must be brought to the oven, which can be difficult when very large parts are involved.

These systems also typically require a substantial electrical connection and system, which adds expense. Also, the oven may have to be preheated for several hours before it’s used, and warm the area around it.

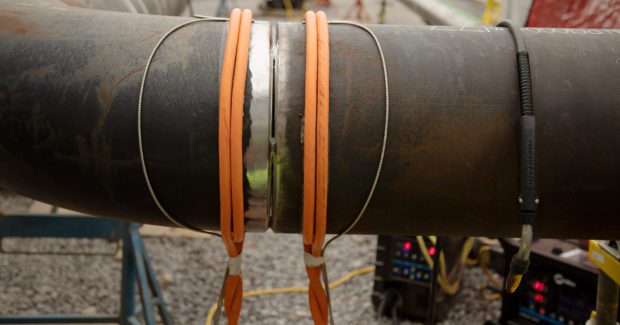

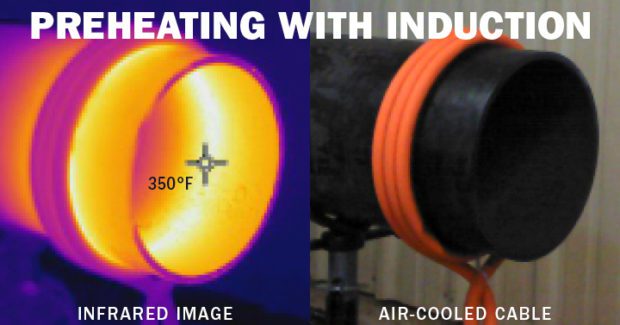

Induction. A magnetic field generates eddy currents within the base metal, heating it from within. Accessories such as cables or blankets are placed on the part to generate the magnetic field.

This method produces a uniformly heated area, making it easy to achieve and stay within even a strict temperature window. It provides safety benefits because the output coils don’t get hot or create an uncomfortably hot environment for welders. It also provides the flexibility to heat many part sizes and shapes, and delivers localized heating where the part is.

New Induction Heating Tool

A variety of accessories are available with induction heating systems. In the past, liquid-cooled cables — which require a cooler and insulation — were the most widely available flexible heating cable option with the heat range of 50 degrees F to 1,450 degrees F on pipes, flat plates, or oddly shaped parts.

Our air-cooled cables deliver the same flexibility without the need for a cooler or liquid-cooled cable connections — just outside air circulation. This can save time and eliminate some costs in preheat applications. Most welding preheat applications — especially those in chemical- or liquid-restricted environments — that are performed using air-cooled blankets or liquid-cooled cables can now use air-cooled cables.

Because air-cooled cables don’t require cooler or coolant connections, they provide the same benefits for flexibility and easy setup without the concerns about losing or damaging connection hoses, damaging coolant connectors on heating cables, or spilling coolant on workpieces or in the work environment. This also greatly reduces the system’s weight.

Welding preheat is often completed on carbon steel heated to 400 degrees F (204 degrees C). Used with our ProHeat 35 induction power source, our air-cooled cables are rated for up to 400 degrees F in the heating zones around the weld and can be used with pipe diameters of ¾-inch and larger.

In addition, the flexible cables can be bent or shaped to best fit the pipe, flat plate, I-beam, or part to be welded, so they’re a solution that can meet many preheating needs.

Options For Welding Preheat

Many welding applications — especially critical welds in industries such as structural construction, oil and gas, and shipbuilding — require preheat. Minimizing the temperature difference between the arc and the base metal slows the weld cooling rate and lowers hydrogen content, two factors that help reduce the risk of cracking and the potential for a failed weld.

Numerous welding preheat methods are available. Understanding the differences in heating methods can help you choose the one that best helps optimize efficiency, produce high-quality welds, and reduce costs and rework.

Consider the many benefits offered by induction when welding preheat is required. Choosing a different technology for preheating can pay off in faster time to temperature, more consistent heating, and other benefits that help save time and money. Induction heating is a very efficient, fast, and accurate method to preheat steels that’s now more flexible thanks to air-cooled cables.

Subscribe to learn the latest in manufacturing.