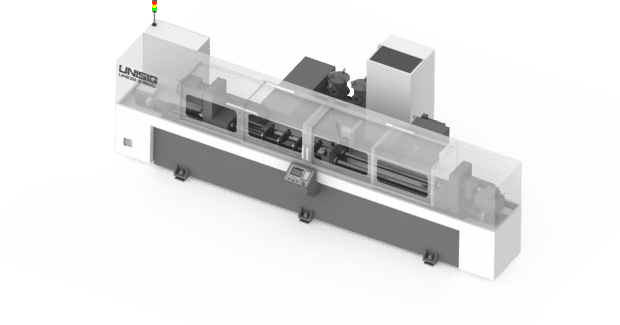

Automation-Ready Gundrilling Machines

Offering operational flexibility, improved performance, and effortless operation, UNISIG’s next-generation UNE Series deep-hole drilling systems are equally effective in high-volume/low-mix and low-volume/high-mix production environments.

Posted: July 7, 2020

Offering operational flexibility, improved performance, and effortless operation, next-generation UNE Series deep-hole drilling systems from UNISIG (Menomonee Falls, WI) are equally effective in high-volume/low-mix and low-volume/high-mix production environments. Engineered to simplify gundrilling for anyone involved in the manufacturing process, the machines are well-suited for industries including automotive, medical, energy, aerospace and defense as well as firearms.

With five models built from two frame sizes, the UNE Series can drill hole diameters from 1.4 mm to 40 mm and depths up to 3,000 mm. The compact frame saves valuable floor space by enabling shops to place the machine close to existing machining center, lathe, or Swiss-style machine for efficient part-processing strategies. Built for quick and easy setup, the machines are also small enough to be relocated when necessary.

For added flexibility, all models are robot-ready to facilitate expansion whenever it fits into a shop’s budget and production schedule.

“A lot of job shops and OEMs want to automate, but lack a timeline for doing so,” says CEO Anthony Fettig. “These feature-rich machines give customers a compact solution equipped with the ability to grow alongside them.”

Several features contribute to performance and productivity:

The single main spindle servo motor provides the necessary horsepower for two-spindle machines. When power is applied in single-spindle mode, however, shops can produce larger-diameter holes to increase their capabilities and add new business without adding a new machine.

An automated door option reduces fatigue and increases throughput by eliminating the repetitive task of opening and closing machine doors, freeing the operator to focus on adding value in other areas.

Unlike pressure-based coolant systems, the machine’s programmable flow-based system provides the right amount of coolant to the tool’s cutting edge. The operator can confidently predict tool breakage and spend less downtime recovering an interrupted process.

Intuitive Siemens controls provide a full process picture at a glance on a rich color interface with touchscreen capabilities. The heavy-duty buttons also function when operators are wearing gloves.

Bases are FEA-optimized and machined on five sides in single setup for highest overall precision. This allows for simplified installation with no foundation work required, and three-point leveling on machines rated up to 1,000 mm long.

UNE Series Overview:

Three two-spindle models available with maximum hole diameters of 12 mm, 20 mm, and 32 mm. Hole diameters even greater when used in single-spindle mode.

Two single-spindle models available with maximum hole diameters of 25 mm and 40 mm.

Five rated workpiece designation options between 750 mm and 3,000 mm.

Solid-carbide, brazed, and indexable gundrill tools.