Tips for Eliminating Back Purge in Stainless Steel Pipe Welding

Switching to a modified short-circuit MIG process instead of TIG for the root pass saves time without compromising an operator’s ability to produce high-quality welds that meet code requirements. Your shop will also save money on consumable costs.

Posted: June 16, 2020

WELDING TIPS COLUMN

BY JEFF ROBEDEAUX

If you’re welding stainless steel pipe with a traditional process like TIG or stick, it likely requires a back purge with argon gas. A back purge removes contaminants and provides backing, but it also adds significant time and money.

Switching to an advanced wire welding process can save time without comprising your operators’ ability to produce high-quality welds that meet code requirements. Here’s how to successfully make the process change.

Why Back Purging is Necessary

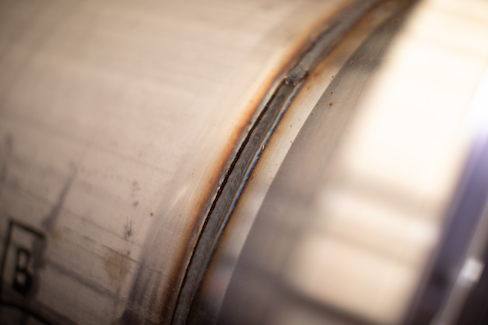

Stainless steel provides corrosion resistance and strength, making it a commonly used material in pipe applications across many industries. But when open-root pipe welding is completed with the TIG process, it typically requires a back purge with argon gas to protect the back side of the weld. Otherwise, heavy oxides can form and cause sugaring on the inside of the weld. This breakdown of the base material is a defect that can lead to rework.

The back purge helps prevent sugaring by introducing gas to remove contaminants, but can be time-consuming and costly — sometimes thousands of dollars per project — especially on larger-bore pipe welds.

A Viable Alternative to Back Purging

Switching to a modified short-circuit MIG welding process allows operations to eliminate back purge on many types of stainless steel pipe welds.

The RMD (regulated metal deposition) process from Miller Electric Mfg., for example, uses precisely controlled metal transfer to provide uniform droplet deposition. The welding system anticipates and controls the short circuit, then reduces the welding current to create a consistent metal transfer. This makes it easier for the welder to control the puddle. Stable short circuits create only small ripples in the weld puddle, which in turn allow consistent tie-in to the sidewall.

With this type of process, welders can more easily control the weld puddle, welding speeds, and heat input. A lower heat input allows the weld puddle to freeze faster.

All these factors combine to result in a less turbulent weld puddle and smoother shielding gas flow, allowing the gas to push through the open root and protect the back side of the weld from sugaring or oxidation. Gas coverage is only needed for a short time because the puddle freezes so quickly, eliminating the need for a back purge.

Twice as Many Welds in the Same Amount of Time

One pipe fabricator saw great productivity gains after making this switch. Founded in 2002, Dixie Mechanical Inc. in Tuscaloosa, Ala., operates a 20,000-square-foot custom-fabrication shop surrounded by 4.5 acres of laydown area. The shop often produces 300 feet to 400 feet of pipe daily for customers in the national and international power and energy, oil and gas, and chemical sectors.

Dixie used to use a TIG root pass with an argon back purge followed by flux-cored fill and cap passes for stainless steel pipe welds. Welders typically spent 20 minutes to 30 minutes each time to set up the argon shielding gas and tape the pipe ends for purging. The gas for back purging also increased the shop’s consumable costs.

The company eliminated back purging on open-root pipe welds by switching to the RMD process for the root pass. Because RMD and flux-cored welding are both wire-fed processes and don’t require lead swaps to change polarities, the move also saved time in process changeover.

With travel speeds two to three times faster than TIG and stick, modified short-circuit MIG has enabled operators to complete more welds in the same amount of time. Dixie doubled the number of welds completed every day without compromising quality standards. The process also provides benefits for ease of use and reduced training time with new welders.

Four Considerations for a Successful Switch

Some best practices can optimize results when switching welding processes to eliminate back purging.

- Check the WPS. It’s likely that changing the welding process will require requalifying the welding procedure specification (WPS). Keep in mind, however, that a process change can deliver fast return on investment through improved productivity and cost savings.

- Make sure the pipe’s clean. Proper cleaning of the inside and outside of the pipe helps ensure good results. To remove contaminants, use a wire brush designed for stainless steel and clean at least 1 inch back from the joint edge.

- Use proper fit-up. A minimum root gap of 1/8-inch between the pipes to be welded allows the shielding gas to flow through and protect the back side of the weld.

- Choose the right consumables. Certain types of shielding gas, contact tips, nozzles, and filler metals can enhance results. For example, a stainless steel filler metal with a high silicon content, such as a 316LSi or 308LSi, will help the weld puddle wet out and act as a deoxidizer. A tapered contact tip and nozzle help localize gas coverage for the root pass.

Saving Time And Money

Making the switch to a modified short-circuit MIG process instead of TIG for the root pass in stainless steel pipe welding can save time and money — helping operations take on more jobs and complete projects faster.

Subscribe to learn the latest in manufacturing.