Quality 4.0 is Achievable When Systems and Culture Merge

Nothing frustrates improvement efforts like software programs that don’t play well together. Brothers Brian and Mitch Olson made sure that didn’t happen when they launched their CNC machining shop by deploying a solution that integrates resource planning and quality management.

Posted: June 24, 2020

MEASUREMENT & INSPECTION COLUMN

BY CHRISTOPHER MENDICINO

As a developer of integrated quality management software solutions, we work with companies that are at different places along the road to Industry 4.0. One milestone on that path is Quality 4.0: automating the quality function and, ultimately, creating consistency through the entire supply chain. That’s where we fit in with our expertise – assisting with integrating a comprehensive quality management system (QMS).

We train deeply on our system’s technical details; for example, automatic ballooning of drawings and 3D models, automatic geometric dimensioning and tolerancing (GD&T) extraction, seamless creation of a centralized database, gage tracking and calibration alerts, reporting, and all the other features. However, there’s one essential aspect we can’t teach: a culture of quality that permeates throughout the entire organization. When a company has that, everyone knows it. It’s palpable.

A culture of quality can make the difference between reaching Quality 4.0 painlessly and quickly or experiencing multiple roadblocks. The good news is that no matter where your company is on that journey – both in terms of systems in place and overriding mindset – change can happen. You’ll start enjoying the benefits, such as more consistently accurate parts, faster deliveries, and profits, along the way.

Some metal manufacturing companies embrace the culture before they even exist.

Modeled After NASCAR Shops

This was the case with Olson Custom Designs in Indianapolis. When brothers Brian and Mitch Olson launched the business to provide precision metal parts to OEMs and top-tier manufacturers in demanding industries, they didn’t know a lot about CNC machining.

However, they were both sprint car racers and had backgrounds in fabrication and construction. Between the two of them, they knew how to run manual machines and how to build things.

Because they enjoy professional motorsports, they often visited the many impressive NASCAR team machine shops in the Charlotte, N.C., area. Those shops served as inspirational models for their own company. If you’ve ever toured a NASCAR team’s shop, you know what I mean.

Olson Custom Designs looks very much like that: There’s a wow factor effect as you take in the clean lines and branding on the exterior and walk in the front door. The interior office and production areas are spotless, sleek, and clutter-free.

“To get a clean, paperless, quality-driven facility spurred the question, ‘how do we achieve that?’” says Brian. “As hands-on guys, we could figure out the physical aspects of building design, flooring application, lighting, and so on. But we needed advice regarding the CNC machinery; the various software systems such as CAD/CAM, ERP, QMS, ISO and AS certifications; and how best to integrate all the digital aspects of manufacturing. We also got ISO-certified pretty quickly because the credential was paramount to attracting the kinds of customers we wanted.”

Entering the world of data-driven manufacturing without preconceived notions or knowledge of conventional methods, however, turned out to be a strategic advantage. The Olsons didn’t know any of the old ways of doing things that can hinder change. They earned additional, specific, industry quality certifications and requirements beyond ISO. They invested in new, multi-axis CNC machines and precision measuring equipment.

“Thankfully, I was able to pick up on the CAM programming and run the CNC machines quickly enough to start making parts,” says Brian. “We didn’t have the ‘I’ve been doing it this way for 30 years and this is how we do it’ mentality, so we approached everything with fresh eyes and sensibilities. To us, it was obvious that the way to go was to be as efficient as possible with systems and automation.”

And the customers came. They came from such critical industries as aerospace, defense, medical, agricultural, and motorsports.

Integration Eliminates Technological Obstacles

From the systems standpoint, the brothers knew an enterprise resource planning (ERP) system would be vitally important. To that end, they chose ProShop by Adion Systems, which functions more as a digital ecosystem across the entire enterprise than a conventional solution for tracking orders. They particularly like how ours captures machining data from the machine tool and interfaces with our High QA Inspection Manager, an integrated QMS.

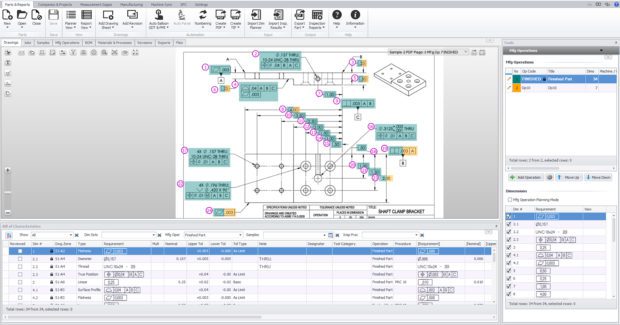

With regard to the QMS, they’ve experienced significant time savings via automatic ballooning of drawings and GD&T extraction. They also appreciate how the solution captures and tracks inspection results and generates reports for customers. Quality manager Larry Culver says these features are particularly helpful with government-customer contracts that require tracking and reporting. However, so far, he’s used the automatic ballooning and GD&T recognition features the most.

“I can balloon a critical component drawing in 10 minutes to 15 minutes versus three to five days previously,” he says.

In a typical sequence, the data from the ballooning and GD&T extraction steps flow into the system seamlessly, establishing the inspection plan for that component, and the production and measurement operations follow. Depending on the customer’s requirements, the system generates first article inspection (FAI) and production part approval process (PPAP) reports immediately.

Because the system is holistic, its integrated QMS software focuses on the quality function. It defines and plans the inspection process and imports inspection results automatically from coordinate measuring machines (CMMs), vision measuring machines (VMMs), arms, and Bluetooth or wireless devices. An employee can also enter data manually from the shop floor using a tablet application.

An integrated statistical process control (SPC) system issues alerts when results approach control limits. One centralized database stores all jobs and all results. A company’s entire gage library can be stored and tracked by category, type, owner, location, and calibration status. When any particular gage needs to be calibrated, an alert pops up, signaling the due date, and the system emails the designated person in the department.

Olson Custom Designs looks forward to using this and other features to further streamline manufacturing processes and procedures.

“It’s all about continuous improvement,” Culver says. “We’ll eventually incorporate all that it can do for us. Until then, our biggest gain has been the transfer of information into a customer report. In the past, it often took me 30 minutes to an hour to check a part, and I’d spend half again that much time just creating a report. Because Inspection Manager downloads information directly into the report generator – accurately – it cut my time by at least half.”

Gaining the Confidence of Demanding Customers

Installing the ERP/QMS solution strengthened Olson Custom Designs’ culture of quality. While the QMS’ functionality is mainly seen on computer screens and tablets, it contributes in a massive way to what can’t be seen: paper.

The Olson brothers have created the clutter-free production area they envisioned when they dreamed of having their own manufacturing company. But pretty is as pretty does, right? It’s one thing to have everything look neat and clean and another to have consistently accurate parts and happy customers. Olson succeeds at both.

“Certainly, it’s impressive when a prospective customer tours our facility; and when we started, that was the main thing we had to show,” says Brian. “However, our cleanliness gave people the confidence to give us a chance. After that, we had to prove our nice-looking shop reflects our work’s quality and isn’t just window dressing. And that’s how we’ve grown in a relatively short amount of time.”

Contributing to the new customers’ confidence, particularly those in the aerospace, automotive, defense, and medical industries, is the system’s ability to generate accurate compliance reports. The system creates, populates, and delivers AS9011, EN9100, AS9102, QS9000, ISO9000, TS16949, APQP, AIAG, 21CFR, and ISO13485 reports, and more.

Advanced CNC machinery integrated with digital, data-driven systems. A pristine, paperless facility. These are the two pillars that support the foundational culture of quality at Olson Custom Designs.

Do you have a culture of quality at your shop? If not, raise the idea at the next team meeting. Talk about it philosophically at first, then list the how-to action items and assign tasks. If you’ve already nurtured such a culture or have started but keep hitting potholes, such as too many different software programs that don’t communicate well with others, fix it with an all-in-one system. Before you know it, you’ll begin reaping the benefits that Quality 4.0 can bring to your customers and your supply chain.