Pendant Application Provides Common Interface for Two Power Source Brands

Does your shop use Lincoln Electric or Miller power sources? If so, Yaskawa Motoman’s universal weldcom interface (UWI) enables welders to easily control any process or parameter including amperage, voltage, and wire feed speed.

Posted: June 22, 2020

The universal weldcom interface (UWI) pendant application from Yaskawa America Inc.’s Motoman Robotics Division (Dayton, OH) enables full utilization of the advanced capabilities on select Lincoln Electric and Miller digital welding power supplies. UWI enables easy control of any weld process or parameter, including voltage, amperage, and wire feed speed through a common user interface for either brand.

Highly functional, the UWI can filter weld modes based on process type, wire size, wire type, and gas type. Up to 16 processes from the power source library can be defined for easy access within the interface. Up to 1,000 custom arc files with specific processes and parameters are available for use in motion programming.

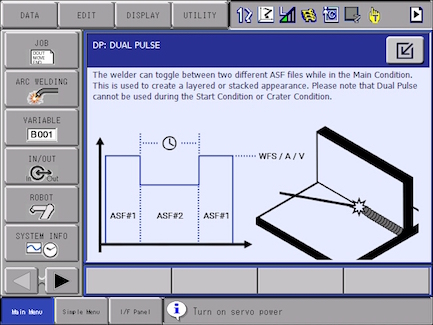

Welders can easily set up to six process parameters, such as pre-flow, start, main, crater, and finish condition, in a weld sequence. Standard functions such as arc-retry, arc monitor data enable, restart, and weld line shift are conveniently utilized. Dual-pulse function allows alternating between MIG weld parameters and settings for aesthetically pleasing TIG-like cosmetics.

Weld settings use terminology that matches the user’s preferred power source. Standard ARCON commands eliminate the need for complicated macro jobs. Programming with arc file interface or inline instructions is supported. Easy-to-access graphical help screens explain terminology and functions.

The interface is fully compatible with arc welding performance tracking features native to the power source. Live weld status is presented on the IF panel display or graphic arc monitor. Weld data can be exported for use in PLCs and part quality serialization. Arc Monitor results from Miller Insight Centerpoint or Lincoln CheckPoint Production Monitoring can be used for alarms or reported to PLCs. Hardware communication for diagnostics is also monitored and logged.

UWI can be used on up to four AR-series arc welding robots with YRC1000 controller (YAS2.81.00-00 firmware or higher). It’s compatible with the Miller Auto-Continuum 350 or 500 and the Lincoln Power Wave with ArcLink XT. A simplified networking utility enables easy setup between robots and welders.