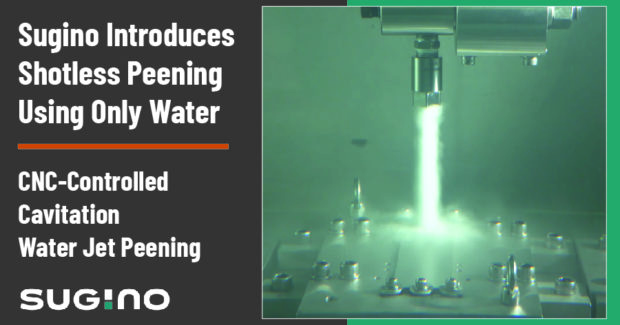

Peen and Wash Simultaneously With Shotless Process That Uses Only Water

Sugino Machine adds waterjet peening with up to 5-axis CNC control to its lineup of equipment that uses water to atomize, deburr, and clean. Peen inside holes, tubes, and cavities without masking or the waste and mess of standard shot peening.

Posted: June 12, 2020

Shot peening improves the fatigue strength and life of metal parts by blasting the surface with ceramic, glass, or metallic beads. While effective in achieving plastic deformation, the process generates waste and requires masking as well as cleanup.

Sugino Machine Ltd. (Itasca, IL) is adding waterjet peening (WJP) with up to 5-axis CNC control to its lineup of water-based solutions for atomizing, cleaning, cutting, and deburring metals. High-pressure water is jetted into still water at high speed from the company’s cavitation-promoting (air bubble) nozzle; gigapascal (GPa)-class impact force of 143,000 psi that occurs when bubbles collapse near the workpiece produces a peening effect. WJP applies compressive stress to a depth of about 1 mm from the surface.

As a shotless peening method, WJP doesn’t require a secondary cleaning process. In addition to increasing fatigue strength of steel and aluminum alloys, applications include prevention of stress corrosion cracking in the welded parts of structures and post-processing in additive manufacturing.

Booth S-338566