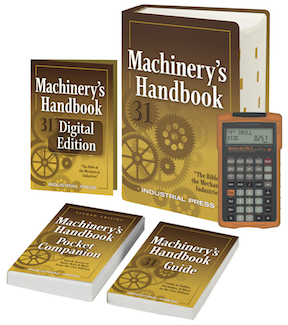

Must-Have Technical Reference Releases 31st Edition

Since first published more than 100 years ago, Machinery’s Handbook has been considered the principal reference tool for engineers, designers, drafters, metalworkers, toolmakers, and machinists.

Posted: June 9, 2020

Almost 100 pages longer and available in toolbox, large print, and digital formats, Machinery's Handbook 31st Edition contains revised ASME and ANSI standards including ASME Y14.5-2018. Companion volumes and combination packages are also available.

Published by Industrial Press Inc. (South Norwalk, CT), Machinery’s Handbook is recognized as an authoritative but easy-to-use reference tool. Comprising almost 3,000 pages, the 31st edition of the “Bible of the mechanical industries” maintains this tradition, providing information including:

- Additive manufacturing: Experts compare traditional machining to 3-D printing materials, techniques, and workflow

- Machine elements and operations: Expanded coverage of CAD/CAM operations, boring, nontraditional cutting methods, o-rings and glands, and transmission chains

- Manufacturing and materials: Using powder metallurgy standard and tool steels, manufacturing stresses, and preventing corrosion

- Metal casting and molding: Working with iron, steel, nonferrous metals, and alloys; and modeling and design considerations

- Metalworking processes: More on brazing, soldering, welding, nondestructive testing, forming sheet metal, mill finishes, passivation, electropolishing, and plating

- Threads and threading: The latest series and selected combinations for unified screw threads.

Booth E-121392

Subscribe to learn the latest in manufacturing.

More fabricators are using larger-diameter grinding wheels and flap discs for their grinding, material removal, and blending applications instead of 4.5-inch options — and with good reason.

More fabricators are using larger-diameter grinding wheels and flap discs for their...