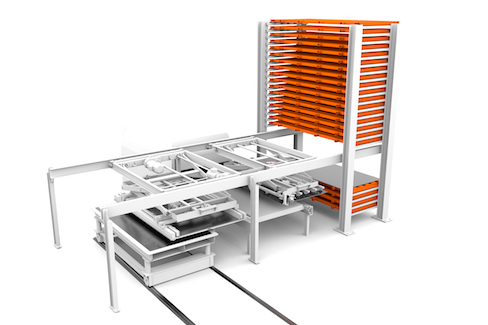

Link Sheet Metal Storage And Processing In One Completely Automated Process

KASTO’s manipulator for automated sheet metal handling saves time and provides cost advantages by seamlessly connecting the company’s fully automatic storage systems with laser cutting machines made by a range of manufacturers.

Posted: June 23, 2020

Because fully automated material flow saves fabricators significant time and money when processing sheet metal, KASTO Maschinenbau GmbH & Co. KG (Achern, Germany) has added a manipulator for unmanned material handling to its product portfolio.

The sheet metal manipulator can be used to separate sheets, feed processing machines, and remove parts and remnants. A vacuum cross bar picks up individual sheets in pre-prepared packages from the storage facility and places them on the laser cutter’s table. Parts and residual sheet skeleton can be removed from the machine’s working area using the rake cross bar. This permits unstaffed production at high throughput speeds and relieves employees of the laborious and potentially risky task of handling the large-format sheets.

The solution works with various brands of laser cutters so customers can configure a complete, tailor-made system based on the machine of their choice. Customers also have various options for sheet metal storage technology, including KASTO’s Unitower and Uniline systems.

With its compact and space-saving design, the manipulator can be easily integrated into almost any production environment. This seamless connection of storage facility and processing machine is an economical and sustainable alternative for both steel distributors and industrial manufacturing companies.