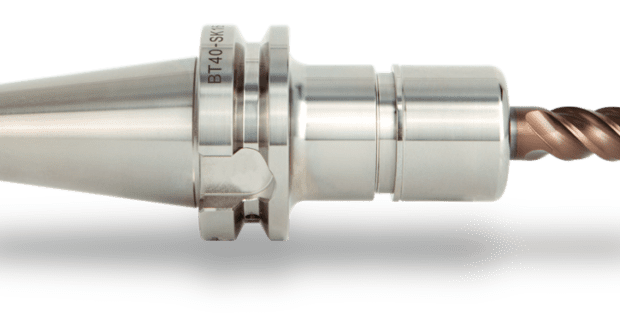

Collet Chucks Provide Flexibility Without Compromising Runout Accuracy

Available in a wide variety of toolholder lengths and diameters for optimal rigidity and clearance, Samchully Workholding’s SK series provide 1 micron runout accuracy as well as three times better runout repeatability and double the gripping force of a comparable ER collet chuck.

Posted: June 12, 2020

General-purpose collet chucks such as ER, TG, and DA hold a wide range of cutting tools, but often lack the runout accuracy to consistently satisfy machining applications with tight tolerances. SK collet chucks from Samchully Workholding Inc. (Lake Forest, CA) resolve this conundrum by striking an optimal balance between flexibility and runout accuracy.

Six SK series provide a wide variety of toolholder lengths and diameters for optimal rigidity and clearance. Capable of holding cutting tools ranging from 0.040-inch to 1 inch, they provide 1 micron runout accuracy at the collet bore and at least 0.0002-inch for a cutting tool (measured at 4X diameter from the collet face). Their 8-degree taper collet provides three times better runout repeatability and double the gripping force of a comparable ER collet chuck. These features make the collet chucks ideal for job shops seeking to use fewer holders with a wide range of tool sizes for precision drilling and aggressive milling.

The SK series is offered in standard and high-speed versions for general-purpose machining and high-rpm applications. Balanced up to G2.5 at 25,000 rpm, precision machining is achieved for cutting applications using small cutting tools or high-speed aluminum milling applications. A smooth nut on the high-speed version prevents coolant dispersion and reduces vibration, resulting in superior finishes.

The collet chucks are offered in dual-taper and flange-contact BT and CAT that immediately improve the performance of any matching BT or CAT dual-contact spindle in two ways.

Flange contact adds 50% more surface area contact between the spindle and the toolholder compared to taper-only contact, enabling more aggressive cuts by increasing rigidity. Depending on the cut, customers can expect productivity to increase 15% to 40%.

BT and CAT spindles with rpms exceeding 20,000 necessitate the use of dual-contact holders. Centrifugal force and thermal expansion cause the spindle taper to expand at high speeds. Because its retention knob is under constant force in the spindle, a single-contact toolholder is drawn higher into the spindle as the spindle expands. This produces minor Z-height deviations from the original tool length offset result in variable machined dimensions or witness marks. Dual contact therefore enhances finishes and machining results.

The collet chucks are also offered in HSK40A – HSK100A and PSC (polygon shank cone) 50-, 63-, and 80-size tapers to address a wide range of machining center spindles and applications.

Booth W-431654