CAM Software Supports Two Additive Manufacturing Processes

DP Technology has tweaked its flagship Esprit CAM software platform to serve a growing fabrication market: 3-D metal printing using powder bed fusion (PBF) and directed energy deposition (DED).

Posted: June 9, 2020

DP Technology’s (Camarillo, CA) computer-aided manufacturing (CAM) software program – Esprit – CAM program software can now be used for two additive manufacturing (AM) processes: 3-D metal printing using powder bed fusion (PBF) and directed energy deposition (DED).

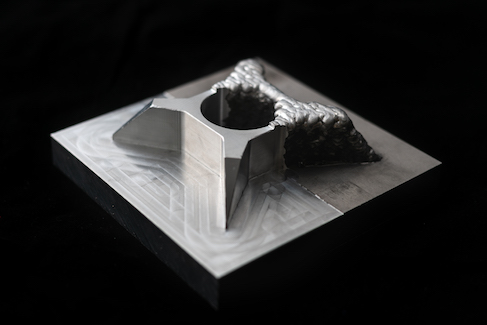

With powder bed fusion (PBF), a heat source (often, but not always, a laser beam) melts and fuses raw with powdered material to create an object. Esprit Additive for Powder Bed is an add-in application for the SolidWorks computer-aided design (CAD) program that’s compatible with any file SolidWorks supports.

Features include Part-to-Build, which automatically assigns exposure strategies based on simple inputs from the user. Another feature is a slicer that boosts accuracy thanks to a parametric workflow model; once the part is ready to slice, it may be imported to the job environment as many times as needed.

“This optimized workflow saves users even more time by eliminating the need to repeatedly define the manufacturing information,” says Clement Girard, product manager for Additive Solutions. “Additive for Powder Bed Fusion improves consistency by ensuring a part is built the same way each time and maintains traceability by recording each step from the original 3D CAD file.”

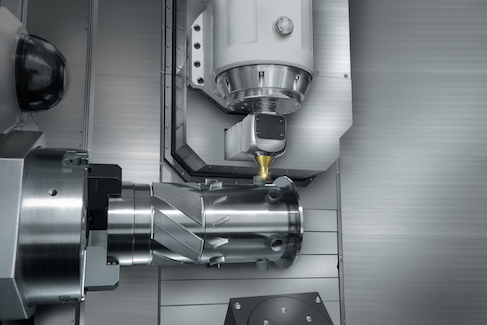

Like PBF, directed energy deposition (DED) also uses a focused energy source, such as a laser or electron beam, to melt material.

Because it provides the ability to control a part’s grain structure, the process is particularly suitable for repairing functional metal parts. For example, DED is often used to rebuild large, expensive, and high-wear components for aerospace, energy, or marine industries such as turbine blades, drill heads, or propellers.

DED is also one of the few metal 3D printing technologies suitable for integration into CNC machines to create a hybrid manufacturing solution. By mounting a deposition nozzle on a multiaxis machining system, highly complex metal parts can be produced faster and with increased flexibility.

After validating the post-processor through collaboration with major machine tool manufacturers and educational institutions, DED cycles for 3-, 4-, and 5-axis CNC machines that include simulation and verification have been added to Esprit. Combined with the software’s subtractive processes and embedded into a single platform, Esprit fully supports hybrid manufacturing.

“We’ve been working with DP Technology on additive manufacturing, including research on DED toolpath trajectories and AM thermal simulation, for more than a decade,” says Frederic Vignat, head of the additive department at Grenoble University in France, the world’s leading research institution on DED technology.

Booth E-133210, N-215321