Autonomous Transporter Forges the Most-Efficient Path Through a Job Shop

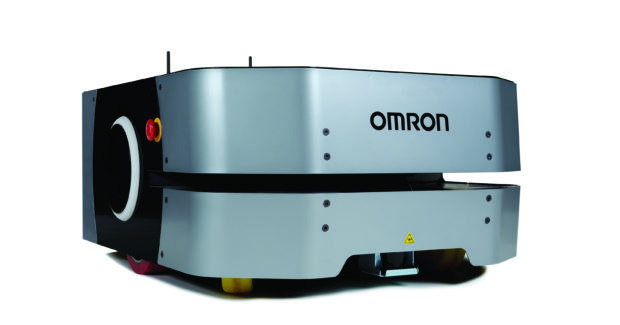

The strongest and most recent addition to the LD Series of autonomous mobile robots from Omron Automation Americas moves 550 pounds (250 kg) while enabling manufacturers to control a fleet of 100 robots using a single system.

Posted: June 24, 2020

Factories worldwide are seeking better ways to increase the productivity and profitability of high-mix production amid a decreasing workforce in industrialized nations and rising labor costs in emerging countries. Autonomous mobile robots from Omron Automation Americas (Hoffman Estates, IL) lower labor requirements and increase workplace safety by automatically calculating the best route to avoid people and machines when moving anything from one place to another.

The LD-250 carries payloads of up to 550 pounds (250 kilograms), ideal for moving things like transmission blocks, automotive seat frames, and voluminous packaging materials that are bulky as well as heavy. Combined with Omron’s Fleet Manager, which enables manufacturers to control multiple mobile robots with different payloads via one system, the products help companies configure a more flexible and optimized material transport system. Companies can manage traffic, battery charging requirements, and vehicle navigation for a fleet of 100 types of robots.

In addition to an extra-sturdy structure that carries unwieldy items traditionally transported in employee-operated carts, the LD-250 is also highly customizable with special conveyor tops, courier systems, and adaptive material-handling mechanics. It also takes advantage of several Omron technologies, such as the high-accuracy positioning system (HAPS), side lasers, and Acuity vision localization, that improve performance.

The integration of the LD-250 with Omron’s TM Series collaborative robot will also open up a new market for heavy-duty mobile manipulators that can handle manipulation tasks along with material transport.