Wireless Communication Capability Enables Speedy Shop-Floor Quality Control

Mahr depth gages transmit measurement data wirelessly, simplifying recording and documentation and facilitating networked production. Pocket-sized 30 EWRi travels easily all over the plant floor; 30 EWR-U and 30 EWRi-U universal gages open the door to numerous applications.

Posted: May 15, 2020

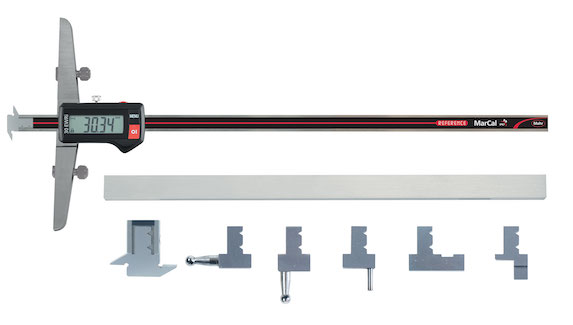

An expanded line of digital depth gages from Mahr Inc. (Providence, RI) includes the pocket-sized 30 EWRi as well as 30 EWR-U and 30 EWRi-U universal depth gages with interchangeable anvils.

Two of the three models transmit data wirelessly, eliminating troublesome cables and speeding quality assurance by enabling measurements to be taken on the shop floor. With the touch of a button on the instrument, keyboard, timer, remote control, or foot switch, data is sent from the gage to an i-Stick radio receiver plugged into the USB port of the user’s computer.

The 30 EWRi with integrated wireless data transmission provides a 0.06-inch (1.5-mm) contact and 1-inch (25-mm) gaging range.

The 30 EWR-U and 30 EWRi-U come in measuring ranges of 0-12 inches (300mm) or 0-20 inches (500mm), and each has resolution of 0.0005 inches (0.01mm). The 30 EWR-U includes MarConnect output for wired USB RS-232 or Digimatic; the 30 EWRi-U transmits data wirelessly.

Five interchangeable anvils expand the capabilities of the universal gages, which also come with a standard 30 Ud twin hook anvil for measuring basic widths and distances. Instead of costly special alternatives, they make it easy and cost-effective to measure depths and recesses with various configurations of ball- or chisel-style anvils.

MarCom 5.2 software enables fast and easy setup of measuring stations with wireless (or wired) data transfer to the PC, and cell control is highly flexible. Values from connected devices can be automatically transferred into separate Excel columns, tables, or files, ensuring reliable documentation. The software also transfers readings through an integrated virtual interface box to SPC/CAQ software such as Q-DAS or Babtec.