Ultimate Nesting for Punching Machines

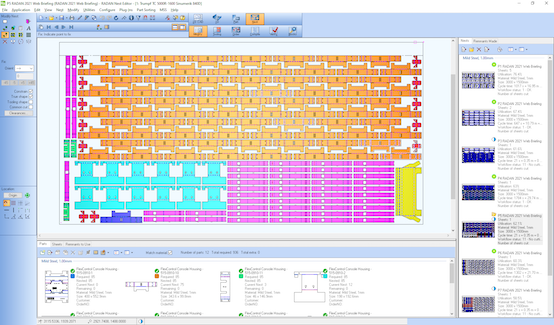

The latest RADAN software for sheet metal fabrication provides savings on raw materials and quicker nesting production. Users can produce more parts per sheet, so it takes less time to produce a batch – saving about 50 minutes per day for 80 nests.

Posted: May 14, 2020

CAD/CAM, tubes, bending, quoting and a specialized CAD-for-CAM modelling tool all benefit from the enhancements comprised in the latest version of RADAN software for sheet-metal fabrication from Hexagon Production Software.

Manufacturers operating punching machines and want to optimize batches of nests, can now use Radnest Ultimate on a punch press.

Product Manager Olaf Körner says that optimizing nests with the module can reduce the number of raw-material sheets used by eight percent per year. “Manufacturers spending hundreds of thousands of dollars a year on materials will find that this gives them massive savings,” he says.

He adds that while many manufacturers would automatically notice the material savings, more parts per sheet means it also takes less time to produce a batch. “Another welcome, additional savings,” Körner says.

Set-up sheets can now be automatically generated and sent to each machine, saving around 50 minutes in an average day of producing up to 80 nests. The NC code for the job goes to the machine, and the set-up sheet to the operator. “Now it’s done through a simple tick box, and the sheet is always up to date, with no chance of omissions or errors.”

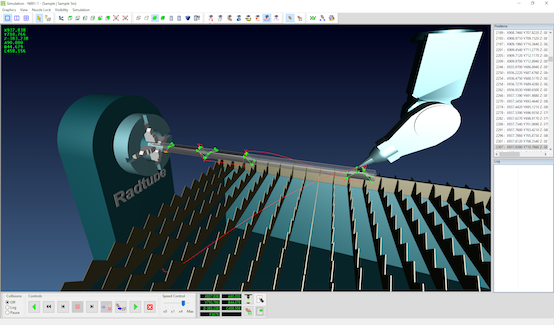

Radm-ax/Radtube

The latest release overcomes the issue of hazardous holes – created when pieces of metal are left in a dangerous position after a hole has been cut in a tube. Extra cuts can now be carried out, dividing the slugs into smaller chunks, which fall out more readily.

Three important updates to multi-part nesting:

The ability to import order and job numbers, which include details for which order the parts belong to so that they can be kept together for assembly, is among the updates. This allows all parts to be more easily tracked throughout the shop, and is achieved via CSV import, or by manually modifying data in the multi-nester and displaying it.

It is now possible to start manufacturing automatically from a full assembly, without needing to take individual shapes, sizes or material into consideration. Everything is automatically calculated from the assembly and into the nesting engine with the order and job numbers.

A new Tube Purchasing Report has been added that details which materials are required for a job, whether it will be collected from existing stock, or needs to be purchased.

Common-line cutting can now be carried out even if the ends have cutouts in the design. Two overlapping cuts can be converted to a common-line cut sequence where two specific aspects are met: Firstly, the end features must be produced with a single cut and, secondly, the end cuts must overlap by at least 25 percent. This means that up to three quarters of all tube parts can now be considered for common-line cutting.

Radbend

A new option improves collision checking during automatic sequencing. Körner explains that this is particularly valuable when bending long, thin parts, such as guttering.

“If the channel is particularly deep and is bent in the wrong sequence, it could become jammed in the press brake, and clamped around the tools. This type of part can be sequenced in such a way as to guarantee that collisions won’t happen.”

Radbend now reduces handling when calculating sequences automatically by reducing the need for tool and part rotations. “Every time operators have to turn a part around, either by themselves or with a colleague, it takes time. This new piece of functionality calculates a better sequence, meaning it can be fed into the machine in little steps, improving the handling.”

The tool editor now also shows important additional information by default, making it more user-friendly.

Radquote

“Cutting strategies can now be specified on a part in Radquote. It asks how the parts are to be cut – for example, whether oxygen or nitrogen is required for a laser part, and what finish is required – as these factors affect the costs,” he says.

Additionally, RADAN 3D drawing files can be added to the quote, complementing its ability to read directly from CAD files created by systems such as SOLIDWORKS, Inventor, Creo and Catia.

Moreover, a 2D shape can now quickly be modified in Radraft and updated in Radquote. “Some quoting systems on the market can’t easily change a part graphically,” says Körner. The benefit of this enhancement to Radquote is that if you’ve received a file that’s not 100 percent accurate, it can readily be edited in Radraft and the updated file read by Radquote.”

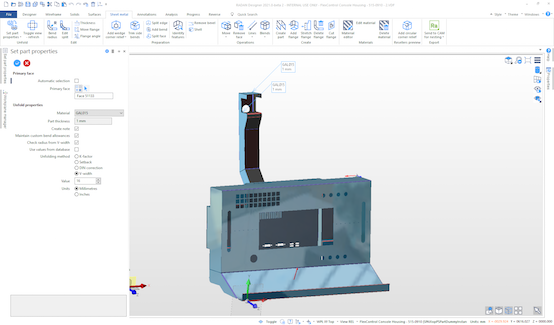

Designer

A number of items with new and enhanced functionality have been added to the Designer module, including “dramatic improvements” for sending the finished design to CAM.

“For example, there are six different ways of sending Designer data into RADAN CAD/CAM, including sending flat patterns of all parts to be added to a nest project, and sending a single part for opening geometry in the part editor,” says Körner.

Designer now indicates bends where the design radius differs from the expected result radius when using V-width as the unfolding method. This is important for the unfolding process, and the finished look of the component.

Feedback is now provided on overlapping unfolds. “Sometimes, when a 3D model is unfolded it doesn’t work – faces clash on top of each other. The user is now notified of this and shown the issue graphically.”

Another new function adds watertight corner reliefs, showing in 2D what it will look like to make it in 3D. The Split Edge command can now also deal with arcs, making it faster to open a closed edge.

In conclusion, Körner says, “RADAN 2021 achieves our target of bringing items of functionality off preview and into the full release. It represents another state-of-the-art version of the software for sheet-metal companies working on models they have designed themselves, or imported as CAD files from other systems.”