Toolholder System Improves Shoulder-Grooving Performance and Reliability

Designed for high-volume production via CNC lathes and multispindle machines as well as automatic lathes, Walter’s G4014-P grooving toolholder and MX22-2L/R indexable inserts with two new geometries provide stability, precision, and indexing accuracy.

Posted: May 18, 2020

Designed for high-volume production via CNC lathes and multispindle machines as well as automatic lathes, Walter USA’s (Waukesha, WI) G4014-P toolholder and MX22-2L/R indexable inserts with two new geometries ensure stability, precision, and indexing accuracy when deep grooving along a shoulder.

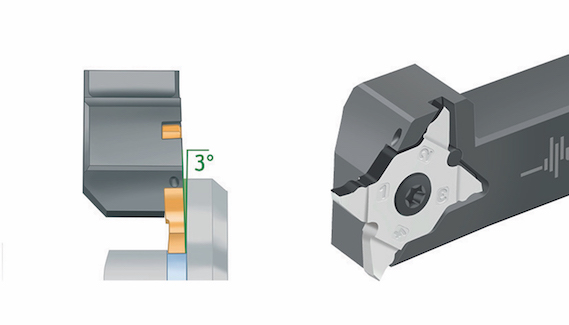

The four-edged indexable MX inserts incline by 3 degrees in the insert pocket and are available in right-hand and left-hand versions. They’re also available in two geometries: GD8 to eliminate interference when grooving along a shoulder and large diameters, and VG8 for finishing operations behind a collar. Because of its reduced space requirements and narrow shape, savings on workpiece material are possible in mass production compared to conventional V-style ISO turning inserts.

Shank sizes ranging from 0.625 inch to 1.0 inch and 12 mm to 25 mm allow for cutting depths up to 0.197 inches (5 mm) and insert widths between 0.059 inch to 0.118 inch (1.5 mm to 3 mm). This selection makes the system particularly suited for high-volume production of smaller components such as camshafts in the automotive industry or precision parts in the medical device industry.