The Great Ventilator Race: Custom Tooling Order Demands Speed Plus Precision

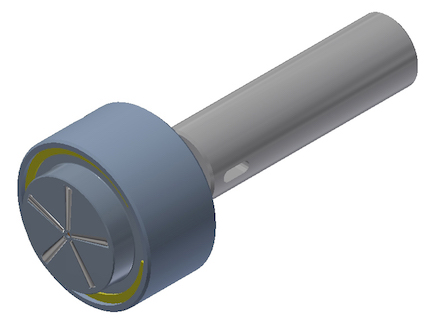

Monaghan Tooling put a new spin on rush order when their distributor’s customer required a specialized burnishing tool for a ventilator component – deeply motivated team collaboration took the job from PO to machining floor in under 24 hours. Engineers determined that a flat-face, multi-roller burnishing tool was the ideal way to achieve the necessary fine micro-finish.

Posted: May 12, 2020

Custom tooling requests are not unusual at Monaghan Tooling Group (MTG) (Dayton, OH), and each gets special attention. But when it’s a matter of life or death, you tend to pull out all the stops. That’s exactly the situation the MTG team faced when they received a request for a burnishing tool to produce a very fine micro-finish on a flat surface of a ventilator component.

New England’s Butler Bros., a Monaghan distributor, had a customer that needed custom tooling to produce 2,500 ventilator components per week by mid-April. The team turned the project around – from purchase order to signed approval print for custom tooling in five hours and 15 minutes. While that breakneck is not the norm, Monaghan and their Elliott Tool Technologies (ETT) partners were committed to help speed the production of critical ventilators to COVID-19 patients nationwide.

“As soon as we heard ‘ventilator’ we made this our No. 1 priority” said Monaghan Tooling Group president Scott Monaghan. Despite the urgency of the request, it was still critical to work within processes at MTG and ETT to ensure that the project was complete with utmost accuracy and speed.

After review of the application, MTG engineers determined that a custom designed flat-face multi-roller burnishing tool would produce the desired surface finish. Following some emails and phone conversations with colleagues at Butler Bros., the decision was made to move forward and place the order.

That started the critical project along its rapid trajectory.

“This wouldn’t have been possible without the teamwork, communication, and shared urgency of everyone at Monaghan and Elliott Tool,” said MTG Operations Manager Andrea Rees. “Knowing that life-saving equipment was on the line motivated everyone.”

The purchase order was received from Butler Bros. at 11:26 a.m. EST. The project went immediately into project design.

At 12:39 p.m., MTG finished creating the engineering project and transferred all pertinent data to the ETT engineering and design team, who started designing the custom tooling.

By 3:14 p.m., the approval drawing was completed and submitted to the customer for review and approval.

At 4:15, MTG received the signed approval of the burnishing tool design. This was submitted to ETT and work began immediately on detailed prints.

Early the next morning prints were released to manufacturing. By 11:00 am work orders hit the manufacturing floor and programming of the necessary machines began.

The project initially had a scheduled ship date of April 14, but ETT and MTG, working closely together, were able to ship the product on April 8 – nearly a week ahead of schedule.

Why Multi-Roller Burnishing Is Ideal for This Application

Multi-roller burnishing worked because it achieves the desired surface finish without secondary processes like grinding, honing and polishing and the inherent time required for these additional set-ups. It produces a 4 to 8 Rs surface finish in one pass, making it a faster process than multi-pass approaches. This repeatable and consistent process improves surface irregularities and tool marks.

Additionally, burnishing increases the surface hardness through the cold working process and compressive forces.

This aluminum component is being machined on a drill press, so achieving the 15 Ra finish is ideally suited for multi-roller burnishing.

The Mechanics of Quick Turn Around

ETT’s modular flat-face tool design ensures quicker design and three to four times faster manufacturing, while adhering to high quality standards. A recent tooling design optimization project allowed ETT to redesign the product line to utilize more standard components for various tools. This reduced the number of custom components required for custom applications, like the Butler Brothers project. Using more standard components helped to shave time from the design and manufacturing process.

“Utilizing design automation tools with the 3D CAD system to automatically generate models, based on application variables, allowed us to slash design time by 50 percent,” said ETT Engineering Manager Ben Lambers.

Although speed is essential – especially when rushing projects through to save lives in a pandemic, precision is paramount. “With custom engineered tooling, no matter how fast you react, if you don’t do it precisely and accurately, speed means nothing,” said Monaghan.

Speed and precision came together on this project thanks to the communication, teamwork and shared urgency of all parties involved. It proved to be vital in the expedited production of ventilator components – and more so to the patients benefitting from them.