Pandemic Underscores Need for Supply Chain Agility

For almost a decade, machine tool consumption in the U.S. has increased and China’s has decreased. As global supply chain emergencies accelerate a manufacturing migration to the U.S., metal fabrication and machining companies that use manufacturing as a service (MaaS) platforms stand to benefit.

Posted: May 26, 2020

BY STEPHANIE JOHNSTON

China’s Hubei province is a manufacturing-and-distribution hub that produces iron and steel as well as parts and assemblies for automotive, medical, food processing, and other industries worldwide. As the local and national governments locked down factories in the city of Wuhan, Ground Zero of the global COVID-19 pandemic, customers around the world clamored for supply chain alternatives to fulfill their customers’ orders.

To facilitate overseas manufacturing, a San Francisco-based manufacturing as a service (MaaS) platform that matches fabrication and machining companies with manufacturers seeking fast turnaround on prototypes and production runs of 100 to 500,000 parts, had opened an office in Guangzhou, China, in 2018. In the early weeks of the pandemic, as factories shut down, Fictiv quickly switched course.

After securing the safety of its Chinese employees, Fictiv shifted capacity to India, Taiwan, and the U.S. to ensure on-time project completion. The platform identified and automatically matched manufacturing partners – the companies Fictiv has approved to produce parts – to customer orders by type, quality, size, and deadline.

- Overseas operations were brought back online four days after the outbreak by shifting capacity to Taiwan and India.

- U.S. operations remained online through China’s outbreak, preventing disruptions to customers’ schedules.

- Asian manufacturing network capacity expanded by 20% in the last week of February and first week of March to accommodate increased demand from projects previously manufactured in China.

- Within two weeks, 15% of Fictiv’s overseas manufacturing orders were shifted to vetted partners in India and Taiwan.

- There were no negative changes to project lead time or cost in shifting this capacity, and Fictiv has experienced zero OTIF (on-time/in-full) issues since opening those new facilities.

This is exactly the type of scenario founders Dave Evans and Nathan Evans had in mind when they began looking for seed money to develop a virtual contract manufacturing platform. With funding from investors including Microsoft Corp. co-founder Bill Gates, they developed a platform that harnesses 27 digital technologies and one patent to upload and analyze CAD design files for manufacturability, secure intellectual property, provide near-instant quotes, direct work to manufacturing partners with idle machines, bill customers, and pay manufacturing partners every month.

“The ability to swiftly shift production shows the advantages of a digital manufacturing ecosystem that creates a self-driving supply chain,” says Dave, who’s CEO. “Fictiv performed exactly as intended, proving our design principle on a global scale.”

Fictiv: ‘Created By Imagination’

As the first employee at Ford’s Silicon Valley Lab in Palo Alto, Calif., Dave Evans oversaw prototyping of automotive infotainment dashboards. At one point, he sent three emails for one job from three addresses – his personal account, his work address, and one from a university – and got three different quotes (Ford’s was the highest). Such discrepancies, along with frustration over the arduous process of sourcing and managing vendors, motivated him to join the ranks of manufacturing technology entrepreneurs.

“We can cut lead times from months and weeks—which is how long I was waiting for at Ford—to hours and days,” Evans told Forbes in 2018. He told the magazine the platform delivers a 3-D-printed product on the same day and injection-molded parts in 10 days. Fictiv can deliver a P20 steel tool capable of molding 100,000 units in two weeks.

Gears for Custom Robots

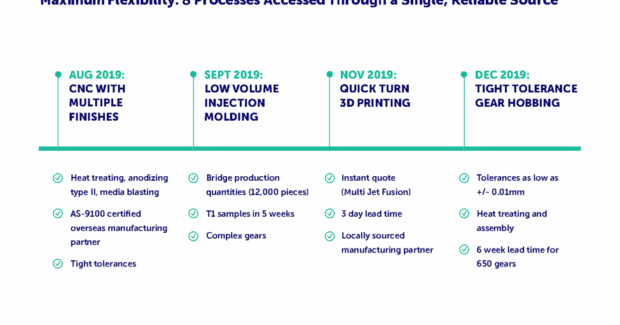

Industrial Robotics, a Pittsburgh-based developer of software and hardware solutions for custom robots, has received 14,500 parts from Fictiv. They range from tight-tolerance CNC machined parts with multiple surface finishes to low-volume injection-molded components to quick-turn 3D printed enclosures to custom-machined gears.

Founded in 2014, the company tried the platform to resolve supplier communication and quality issues.

“Prices for some shops were low, but lead times were too long,” says Founder Dave Rollinson. “Others had fast turnaround, but high prices. Some were automated, but couldn’t manage the specific details for tolerances or surface finishes. We passed up several hundred-thousand-dollar sales because we couldn’t get parts we needed quickly enough.”

Meanwhile, Mechanical Engineer Andrew Willig didn’t like working with overseas suppliers. “Typically, it took about a day to hear back about lead times or where my parts were in the supply chain. Now, we get instant communication that helps us quickly iterate, talk through things on our parts that may need to change, and get updates on parts and shipments.”

10 Million Parts in Six Years

Fictiv’s cloud-based platform combines design, quoting, billing, and logistics systems with an intelligent orchestration engine. These virtual capabilities are supplemented by expertise only a human can provide. Supplier quality engineers (SQE) in the company’s locations support ISO 9001-certified quality management systems that include auditing manufacturing partner factories, inspecting parts, conducting quality control protocol training, and providing design for manufacturability (DfM) guidance.

Over the last six years, Fictiv has manufactured more than 10 million parts.

Fictiv doesn’t disclose the names of manufacturing partners, so I wasn’t able to talk to the companies that supplied HEBI Robotics. Customers, like HEBI, pay on a per-part basis, with pricing calculated using an algorithm that evaluates factors like machine time, cleaning time, part complexity, and raw material usage.

Manufacturing partners don’t pay a fee to belong to the network and there’s no bidding process.

“We can’t guarantee a minimum amount of revenue because we don’t control the markets,” says Evans. “However, unlike other distributed manufacturing platforms, we limit the number of new partners we bring into our network and strategically distribute work to do our best to send each and every partner a target minimum amount every month. This generates trust and high engagement.”

Working with Fictiv minimizes the time and effort a manufacturing partner spends commercializing the business via sales, marketing, customer service. Shops can focus on increasing operational efficiencies by maximizing machine capacity to handle more work.

“Agility has quickly become the singular force driving manufacturing and supply chain management,” says Evans. “Luckily, that’s core strength.”