More Manufacturers Take a Closer Look at Wire Arc Additive Manufacturing (WAAM)

Unlike powder-based additive manufacturing, this second method of additive manufacturing uses a standard high-deposition process and readily available materials. Wire arc additive manufacturing (WAAM) is particularly cost-effective for prototypes and small-batch production runs.

Posted: May 15, 2020

BY MICHAEL FLETCHER

A form of 3-D metal printing, wire arc additive manufacturing (WAAM) is a process by which complex parts that may be difficult, even impossible, to manufacture conventionally are produced. Thanks to significant technical advances over the last five years, the process is an accepted alternative production method for aerospace suppliers and being rapidly adopted by manufacturers in other industries.

International Data Corp. estimates global spending on 3-D printing will reach $23 billion by 2022, a 23% increase from 2018. China, the United Kingdom, and the U.S. are driving most of the growth; but Australia, India, and the rest of Europe are also exploring the technology’s possibilities.

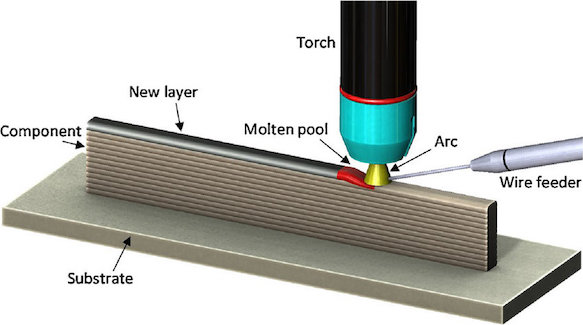

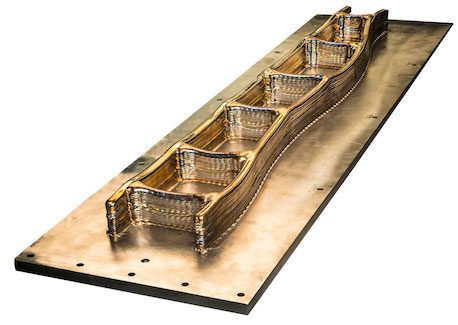

WAAM deposits metal layer by layer using CNC metal printers to form a 3-D shape. Melting techniques such as electron beams and lasers have been used, but they’re slow and expensive. WAAM, which uses high-deposition-rate conventional arc welding, is much more cost-effective.

Maximum part size is in the region of 39.4 inches (1 meter). The process is extremely efficient, typically lowering manufacturing costs 60% compared to conventional CNC metal removal. WAAM’s build rates are faster than powder-bed-based additive manufacturing.

WAAM is most often used when mass production isn’t needed, where rapid prototyping followed by short run production is required. Current applications are in the marine, aviation, and motorsport sectors. However, there’s little doubt that, once further developed and adopted globally, many other industries will exploit the technology’s advantages.

Popular Application #1: Marine Propellers

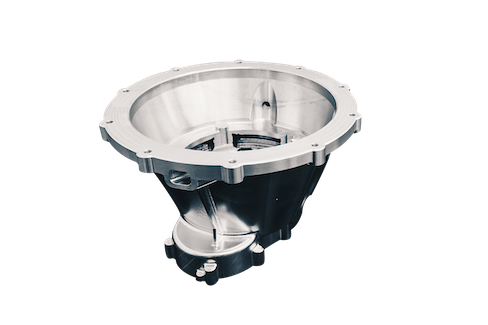

Casting is the traditional method used to manufacture propellers, but requires long lead times. Because the process involves making a mold, casting it, and then processing it, casting can often only be justified commercially for longer runs. WAAM, however, can be used to make even one propeller on short notice. The commercial advantages are therefore very great.

Significant progress has been made in the Netherlands by Damen Shipyards, which manufactured a 51.2-inch (1,300-mm)-diameter propeller weighing 397 pounds (180 kilograms) from a bronze alloy.

The current maximum length is considered to be 32.8 feet (10 meters).

Popular Application #2: Aerospace Components

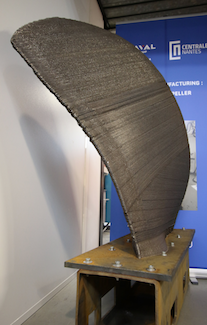

Manufacturers are taking advantage of WAAM’s ability to quickly and precisely produce complex yet lightweight aircraft parts and assemblies from expensive alloys.

Take, for example, wing spars. They’re usually machined from a solid billet or forging, a process that wastes over 50% of the material as swarf. A 3.9-foot (1.2-meter) WAAM demonstration model developed by Cranfield University’s Welding Engineering and Laser Processing Center in England wastes virtually no Ti-6Al-4V (ASTM Grade 5 titanium). Landing gear is another possibility, where cost savings of 70% are expected.

Another project takes WAAM technology a step further. Launched in 2007 with funding from the university’s Innovative Manufacturing Research Center and 15 industry partners, the program seeks to fabricate a complete product in one operation by incorporating a fully integrated robot.

British multinational defence, security, and aerospace company BAE Systems is working with Royal Air Force (RAF) Marham in East Anglia to engineer WAAM-produced protective covers and guards for four squadrons of Tornado GR4 aircraft. BAE Systems has also used the process to produce a 3.94-foot (1.2-meter) titanium alloy wing spar.

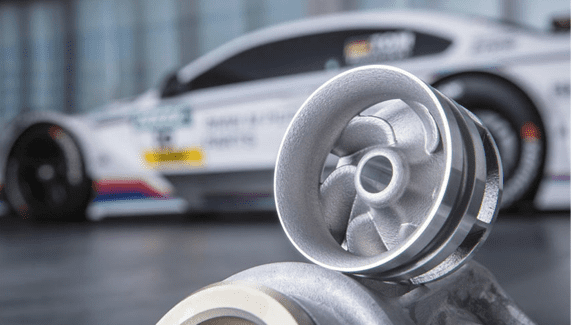

Popular Application #3: Automotive Engineering

There are a range of potential WAAM applications in motor sport where single components must be produced quickly. The process eliminates the casting or forging stage in the transition from digitized drawing to final part. Some items may require final machining operations, but total time from design to finish is very short compared to other manufacturing alternatives.

Large manufacturers such as Bavarian Motor Works (BMW) are among the first WAAM adopters. While announcing the opening of an new additive manufacturing center in 2019, the German company presented a 3-D-printed motorcycle chassis prototype.

One Caveat About the Process

Many alloys may be used for WAAM simply by relying on the welding torch inert gas shroud as protection. However, some materials are much more prone to react with residual oxygen, which can cause fusion zone and surface oxidation. While titanium alloys are particularly sensitive, stainless steels and many low-alloy steels also require additional inert protection. In any event, protecting parts solely by relying on the torch gas is inadvisable.

Flexible enclosures such as the Huntingdon Fusion Techniques HFT Argweld can be purged with inert gas (usually argon). Large enough to accommodate all welding equipment including a robot, they provide protection throughout the entire WAAM process. They also keep oxygen content well below 100 ppm (0.01%), low enough to prevent significant oxidation of sensitive alloys during welding and cooling.

Flexible enclosures cost less than 10% of a metal glove box and 2% that of a metal vacuum system. They also have a very small footprint.

Finally, real-time monitoring and control of purge gas oxygen content is crucial to avert discoloration and corrosion.

Techniques for measuring oxygen content have been available for decades. However, only recently have instruments such as the HFT PurgEye been developed specifically for welding applications.

The instruments combine full-color touchscreen control with on-screen graphical presentation of the oxygen/time relationship. A wireless USB memory stick slot supports data logging and weld certification. Solid state sensors read oxygen levels from ambient down to 10 ppm.