Managing a Manufacturing Plant Through the Coronavirus Crisis

From McKinsey & Company: Manufacturers can follow three guiding principles to keep their workers safe while preparing for increased uncertainty and long-lasting changes to the work environment. Principle No 1: Protect the workforce.

Posted: May 1, 2020

BY VIVEK FURTADO, consultant, McKinsey & Co., Denver office

TOM KOLAJA, partner, McKinsey & Co., London office

CURT MUELLER, senior partner, McKinsey & Co., Chicago office

JULIAN SALGUERO, partner, McKinsey & Co., Miami office

As the COVID-19 pandemic sweeps across the globe, manufacturing organizations face significant operational challenges. Some companies have temporarily shuttered factories in response to government restrictions or falling demand, but others are facing significant increases in demand for essential supplies.

Frontline manufacturing staff can’t take their work to the relative safety of their homes. Plant leaders are therefore looking for ways to operate through the immediate crisis—all while preparing for a potentially much longer period of heightened uncertainty regarding demand and supply, and a lasting need to maintain enhanced hygiene and physical distancing.

Three areas of focus can help plant leaders navigate the transition from initial crisis response to the “next normal”:

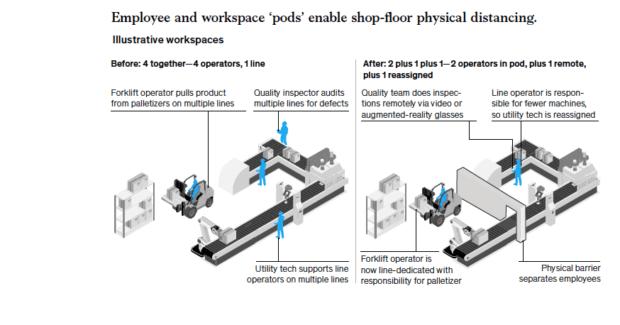

Protect the workforce: Formalize and standardize operating procedures, processes, and tools that help keep staff safe. Build workforce confidence through effective, two- way communication that responds to employees’ concerns through flexible adaptation.

Manage risks to ensure business continuity: Anticipate potential changes and model the way the plant should react well ahead of the fluctuations to enable rapid, fact-based actions.

Drive productivity at a distance: Continue to effectively manage performance at the plant while physical distancing and remote working policies remain in place.

Download the full article from McKinsey & Co.