IBAG North America Offers Factory-Certified Spindle Repair

High utilization rates can hinder machine tool performance. High-speed spindle manufacturer IBAG North America provides uptime by offering repair services including condition evaluation, internal-parts analysis, and rebuilding from its North Haven, Conn., facility.

Posted: May 6, 2020

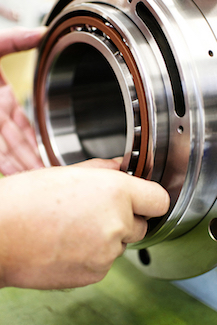

IBAG North America (North Haven, CT) is providing repair, installation, and rebuilding services for all IBAG high-speed spindles and components including drives, chillers, and bearing lubrication systems. All repairs, including bearings, carry a six-month warranty.

Services include full disassembly, wear analysis of all internal parts, ultrasonic cleaning, rotor shaft precision balancing to less than a G1 level, new parts and bearings as needed to return the spindle to factory standards, testing, run-in, and final testing. Data such as housing temperature, vibration, current, and taper run-out is captured, recorded, and saved throughout the entire process per ISO9001 requirements in a database according to spindle serial number.

All work is performed in the company’s Connecticut facility.