Double-Duty Measuring of Big Components

Combining dimensional metrology and surface roughness measurement, the InfiniteFocus G5 from Bruker Alicona provides high repeatability and vertical resolution of up to 10 nanometers. An interface equips the system for fully automatic measurement during production.

Posted: May 15, 2020

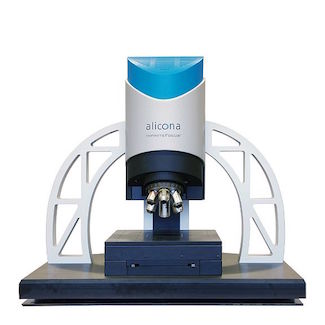

Bruker Alicona’s (Itasca, IL) InfiniteFocus G5 is an accurate, fast, and flexible optical 3D surface measurement system that combines dimensional metrology and surface roughness measurement in one system. Users can achieve traceable high- repeatability results in a vertical resolution of up to10 nanometers.

Combining the technical principle of Focus Variation with vibration-isolating hardware, InfiniteFocus G5 measures form and roughness of large and heavy components. All axes are equipped with highly accurate encoders to ensure precise stage movement. With an automation interface, InfiniteFocus is also used for fully automatic measurement in production.

Vertical surfaces can be probed laterally with Vertical Focus Probing, an extension of the Focus Variation.