Choose the Right Die Material for High-Pressure Die Casting

In the HPDC industry, steel selection can be the most costly problem in the supply chain. An Uddeholm expert discusses how to solve the major causes of die failure: heat checking, soldering, erosion and cracking.

Posted: May 27, 2020

BY SEBASTIAN SIVERTSEN, APPLICATION MANAGER, HOT WORK MATERIALS, UDDEHOLM

Foundries all over the world are working within a system that enables the production of a specified amount of requested casted products to their customer. The production series of these products are set at an early stage and determines the amount of the order. One-hundred thousand identical cast parts can be ordered and the total cost is a direct impact of the amount of tools desired to fulfill the quota. A premium tool steel for high pressure die casting (HPDC) has the potential to fulfill it. This mindset embraces the value of die economy in terms of minimized tooling and downtime cost, and foundries would benefit from adopting it when selecting a die tool steel rather than focusing only on the single die cost.

We will discuss what actions can be considered in the HPDC industry so the correct die steel is selected to solve the most costly problem in the supply chain. The focus will be on HPDC industry, the main market for Uddeholm (Hagfors, Sweden) but the principles apply to all hot applications.

Failure Mechanism

If we asked most HPDC companies what their main die failure is that stops them from achieving maximum die life, the majority would say heat checking and then second would be soldering or erosion. But sometimes you can get “cracking,” which can quickly end production. The most common failure mechanism is explained in Figure 1 above. We have to ask ourselves how we can minimize these problems of heat checking, soldering, erosion and cracking.

To minimize these problems and achieve longer die life four main areas plays a significant role. The first one is design, both part design and die design are crucial to minimize the risk for failure. The second and third, which will not be discussed in this article, are die manufacturing and process control. They can be seen as a guide on how to achieve good quality castings without stressing and damaging the production. The fourth and last one is the selection of die material.

Optimized Die Design

From a die maker’s point of view, the freedom of design can be very limited. However, when die design is performed at the foundry, simulation tools can be very suitable to eliminate critical areas for failure exposure. Several casting simulation softwares are available on the market that can be used in a very efficient way to optimize design for production improvement. Where the simulation software highlights risk for high stresses, the design engineer can make required changes to avoid concentrations of stresses to minimize the risk for cracking. Hot spots can also be detected from a design view; optimization of external cooling could be a solution to avoid potential die soldering. Design optimization can also be made based on simulation of filling which can expose critical areas within the die for local increase of melt velocity and therefore erosion damages.

Die Material

The selection of die material can be decided based on history, availability or solution based in order to achieve long production series.

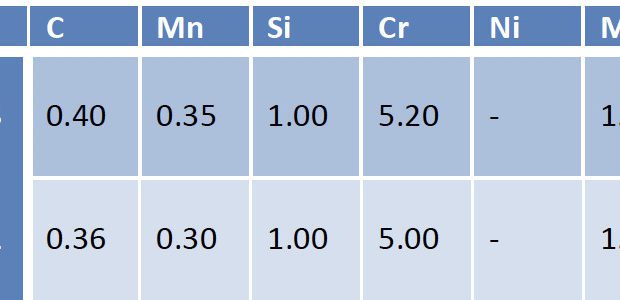

The answer for the main problem of heat checking, the chemistries of 1.2344 (also known as H13) and 1.2343 (also known as H11) are lacking in this area, or they have compromises. AISI H11 & H13 are cheap, easy to buy and they work alright. However, is just OK really want you want? How do these steels compare to modern special chemistry die steels, like some Uddeholms AB can offer?

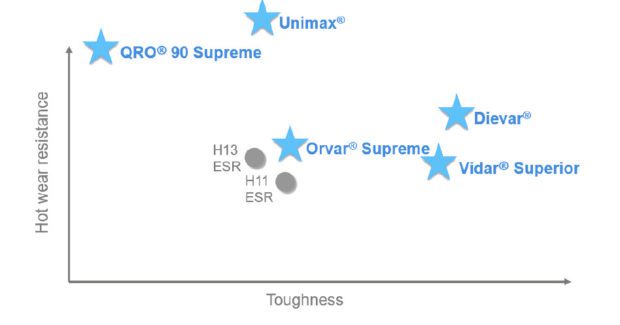

From Figure 4, two key properties had been taken into account: (1.) hot wear resistance that can be directed to erosion resistance and (2.) toughness that can be directed to crack resistance. The comparison clearly shows the improved quality by using Uddeholm steel, even if it is a standard grade like Uddeholm Orvar Supreme that corresponds to H13 and Vidar Superior H11. The main improvement is in toughness, thanks to the high cleanliness level received through controlled and modern production technology.

Two grades rise above the crowd: Uddeholm Unimax and Uddeholm Dievar. To fight hot wear or erosion, Uddeholm Unimax is the most suitable grade, and if cracking is an issue, Uddeholm Dievar is superior.