Wheel Manufacturer Uses Data to Maximize Preventive Maintenance

A global automotive wheels manufacturer worked with two industrial Internet of Things (IIoT) companies — IoTco LLC and Predictronics Corp. – to design and deploy a data-monitoring application that pinpoints potential future failures.

Posted: April 6, 2020

A global automotive wheels manufacturer has provided steel products to every major OEM in the world for more than a century. Award-winning “Predictive Solution Templates” developed for two types of machines at a plant in Ohio are being deployed to other machines at the company’s manufacturing facilities worldwide.

Roll formers bend sheet metal into the cross-sectional profile for a particular wheel and flow-forming spinner machines create a circular disc from a blank to be welded to one side of the wheel. These two machines were identified as the most critical production assets impacting overall equipment effectiveness (OEE) and uptime.

The manufacturer called on two Cincinnati-based industrial Internet of Things (IIoT) companies – IoTco LLC and Predictronics Corp. – to improve uptime by optimizing preventive maintenance schedules and predicting spare part requirements before failures.

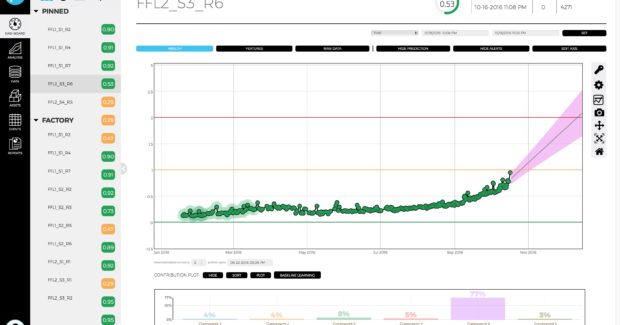

IoTco provides connectivity to any device and cross-IT-system collaboration. Predictronics’ PDX platform is an end-to-end predictive analytics solution that monitors critical assets by collecting and crunching data. Together, they developed and deployed a system to generate a “data lake” of parameters collected from PLCs and appropriate sensor measurements.

PDX was used to construct AI-based health models to be displayed on the user interface. It also triggers alerts and reports to warn employees when a machine’s health is degrading and provide a prediction window pinpointing future failures.

The solution helped determine the tooling component that was causing unexpected machine downtime and saved time, money, and resources by providing the evidence the manufacturer’s technicians needed to create a proactive preventative maintenance schedule.

By transforming data into actionable insights to gain a competitive advantage, the partnership won the National Association of Manufacturers’ 2019 Manufacturing Leadership Award for Artificial Intelligence and Analytics. Artificial intelligence (AI) gives technicians the information they need to keep a failure from happening.