One Thousand Parts a Day to Help Accelerate Medical Equipment Production

TCI Precision Metals executes an all-hands-on-deck initiative to produce a high volume of precision machine-ready blanks that can reduce production time on ventilators, medical testing equipment and other essentials during the pandemic. They’re shipping 1,000 blanks a day and continue to expedite production.

Posted: April 20, 2020

TCI Precision Metals (Gardena, CA) is in full operation to help mitigate the crisis surrounding COVID-19 – they’re producing and shipping machine-ready blanks for critical ventilator and medical testing equipment at a rate of 1,000 parts per day, according to its president and COO, Ben Belzer.

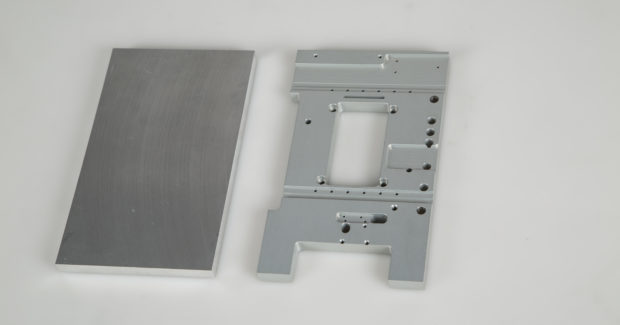

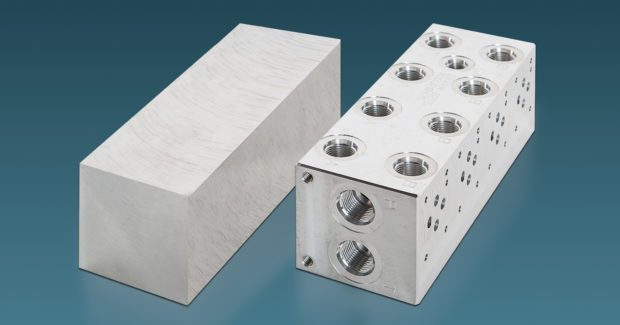

Precision machine-ready blanks can improve production throughput of a part by as much as 25% by eliminating the need for in-house sawing, grinding, flattening, squaring operations and outside processing. Each blank arrives deburred, clean and to customer specifications – guaranteed as close as +/- .0005” dimensionally and as close as .0002” flatness, squareness, and parallelism.

By utilizing machine-ready blanks, manufacturers realize increased capacity, using the time they previously spent in setup and prep to produce more finished parts, faster. During these urgent times, that means reducing the production time of products such as ventilators, durable medical equipment and other essentials.

“As part of our ongoing operations we have implemented a Rapid Response Program, which includes an ‘all-hands’ mandate to prioritize and expedite the production of any and all parts associated with the spirit of [California’s] executive order,” said Ben Belzer, President and COO of TCI Precision Metals. “…We also know there are other manufacturing companies out there trying to respond quickly to critical needs, and we have additional capacity, which is why we are putting out this communication.”