Mold Makers: Universal Spindle Streamlines Milling, Gundrilling

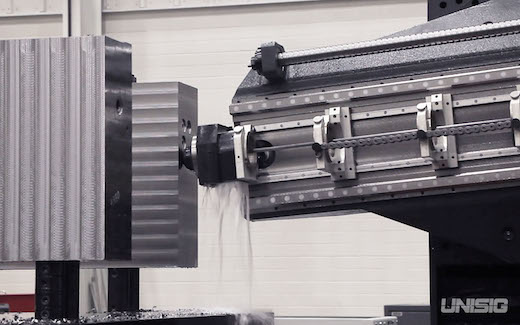

Unisig built the USC-2M and USC-3M for tough applications – both can handle all types of milling and gundrilling metal. And their universal spindle helps users reduce changeover times when switching between those two operations.

Posted: April 23, 2020

To help mold makers achieve the highest levels of milling and deep hole drilling productivity, Unisig (Menomonee Falls, WI) developed the USC-2M and USC-3M, which handle the rigors of both milling and gundrilling metals of all types with a single, powerful universal spindle.

Both models feature rigid, robust frames along with their universal spindles for the toughest applications, all of which help mold makers minimize machining time and maximize throughput.

Mold makers require world-class milling capabilities and accuracy, which is why the new USC designs emphasize rigidity and stability. With CAT 50 spindles up to 40 horsepower, the machines deliver high-torque milling capabilities for aggressive metal removal and shorter cycle times.

“We believe mold makers will truly benefit from the machining capabilities of these two new models,” said Anthony Fettig, CEO of Unisig. “By introducing a pair of universal spindle options, we now offer manufacturers of all sizes a complete line of mold making solutions. The new machines exemplify a continuation of our commitment to meeting customer needs without compromising on quality or accuracy”.

Thanks to the single, universal spindle designs of the USC-2M and 3M, mold makers can reduce changeover times when switching between gundrilling and milling operations. Also, a 60-position automatic tool changer helps further minimize nonproductive time.

Both models can run on oil and water-soluble coolant, as well. For further time and cost savings, the USC-2M and 3M feature fully enclosed machining envelopes that are installed above the shop floor, allowing manufacturers to avoid time-consuming, costly below-ground installations.