Walter Expands MX System; New Thread Former Reduces Torque

Capto toolholders and insert widths expand applications for users of the Cut MX grooving system. The TC410 Advance HSS-E thread former can be used universally for blind and through-hole threads in most materials.

Posted: March 4, 2020

Two Walter USA LLC (Waukesha, WI) products expand applications for owners of a grooving system and provide a new thread former.

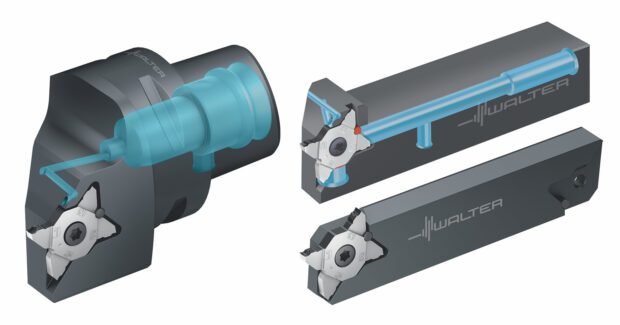

Capto toolholders and insert widths are available for the Cut MX grooving system. Featuring enhanced rigidity and modularity and a tapered polygonal shape that handles torsional and bending forces with ease, the interface can be used for lathes and turning/milling centers.

With the Capto monoblock tools (C3–C6), the MX system can now also be used on machines with Capto interfaces. Parting blades were added to work with automatic lathes and multispindle machines.

Walter completes its range with new grooving inserts and toolholders for larger insert widths. Where previously only 0.031 in (0.80 mm) to 0.128 in (3.25 mm) were possible, insert width now ranges up to 0.222 in (5.65 mm) including common dimensions 0.125 in (3.18 mm), 0.157 in (4 mm), and 0.196 in (5 mm). Maximum cutting depth is 0.24 in (6 mm). These extensions make new applications possible for Cut MX users, from small-parts production where a high degree of precision is needed, to job shops where the focus is on fast, precise tool changes and cost efficiency.

The Cut MX uses dowel pin location to prevent improper assembly of inserts into the holders. That and the horizontal seating surface provide positioning accuracy and diameter repeatability, eliminating the need for test cuts after every insert change. The four-edge indexable inserts can be used after one or more cutting edge breaks. The inserts also have a long life span due to Walter’s precision cooling and Tiger-tec Silver grades.

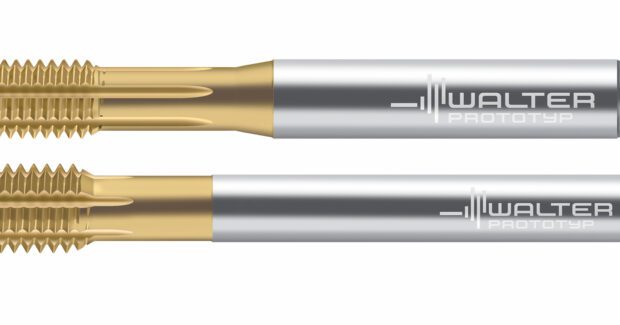

The TiN-coated TC410 Advance HSS-E thread former is cost-effective even for small and medium batch sizes. It can be used universally for blind and through-hole threads in most materials, with primary application in ISO material groups P, M, and N and ISO K and S as a secondary application.

Advantages are superior performance, reduced torque, and longer tool life because of new geometry and a post-treatment after the coating process that provides a smooth surface, reducing friction between the tool and the workpiece as well as the amount of heat generated.

The thread former is available with lubrication grooves for applications that need help getting coolant to the area where the forming is happening, or without lubrication grooves for when the coolant is already pooled in the hole. Deeper threads up to 3.5 × D N can be produced in certain materials.

Various covering thread styles, thread tolerances, and shank standards, including an option for LH threads, are also available.

Walter USA LLC, N22 W23977 RidgeView Parkway West, Suite 100, Waukesha, WI 53188, 800-945-5554, www.walter-tools.com/us.