Sustainably Sourced Metal Powders for Additive Manufacturing

6K’s UniMelt microwave plasma platform converts recycled material into premium powder. The technology processes almost any metal type, alloy, or ceramic feedstock, which means any alloy that’s machined has the potential to become powder.

Posted: March 3, 2020

6K (North Andover, MA) has launched the first sustainable additive manufacturing (AM) powders using a process that converts certified chemistry machined millings, turnings, and other recycled feedstocks into premium AM-ready metal powder.

The company’s two-step process involves reclaiming metals and alloys from subtractive manufacturing and other operations. The 6K Additive team is reclaiming and selling over 500 tons of Ti-64 per year into the aluminum alloying industry for aerospace, medical, and automotive products.

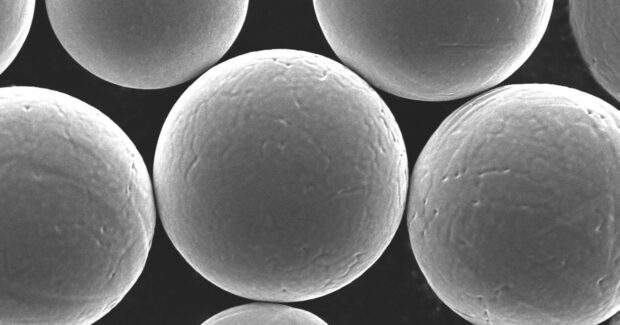

This material provides an engineered feedstock for 6K’s microwave-based UniMelt plasma technology. The process creates a highly uniform and precise plasma zone with zero contamination that’s capable of high throughput production of advanced battery powders, phosphors, and AM materials. The resulting powders have high sphericity, zero porosity, and high flowability and tap density.

Through its reclamation strategy, 6K can target powder size distribution to AM process – binder jetting, direct energy deposition (DED), electron beam melting (EBM), laser-based powder bed fusion (L-PBF), or metal injection molding (MIM) – to produce three to four times more than gas atomization. It can also create powders that haven’t previously been possible, those engineered from non-eutectic alloys such as high-entropy alloys or designer aluminum alloys capable of printing in powder bed fusion systems.

6K plans to extend its capability to feedstock created from AM support structures, non-conforming AM parts post-print, and other unique inputs. Its goal is to use 100% of the materials that enter the supply chain, giving AM end-users a new way to manage project costs and control their supply chain while advancing toward a circular economy in AM.

6K Inc., 25 Commerce Way, North Andover, MA 01845, 978-258-1645,

fax: 978-655-3794, www.6kinc.com.