Simplified CAD Models for Digital Factory Planning

Reading many common 3D formats, CoreTechnologie’s 3D_Evolution Simplifier reduces the number of elements in large CAD models to enable smooth, fast processing.

Posted: March 12, 2020

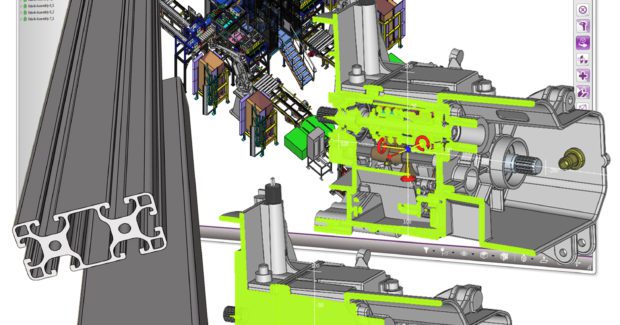

In digital factory environments, engineers face the challenge of too-detailed CAD models generating heavy data, which prevents a smooth handling in factory planning software tools. CoreTechnologie (Moembris, Germany) has announced its latest version of 3D_Evolution Simplifier has a DGN interface function that automatically generates envelope geometry, especially for all major visualization tools. With the number of elements greatly reduced, the Simplifier enables a smooth and fast processing of large CAD models.

The 3D_Evolution software reads 3D formats such as CATIA, JT, CREO, NX, Solidworks and STEP without a CAD license and automatically generates envelope geometries based on the exact, original model. The technology extracts the inner geometry of the models and creates an outer shell as a closed volume for conversion into CAD or factory planning systems such as Microstation, Process Simulate or PDMS.

In addition to deleting the internal geometry, holes, fonts, radii and other details that are unnecessary for the planning process are also removed. The internal bodies can be identified and automatically deleted by a “Shrinkwrap” tool so only bodies that are visible from the outside and relevant for the planning process are retained.

In all stages of simplification and conversion, healing functions ensure that geometry errors in the CAD models are analyzed and cleaned up in order to generate volume bodies – closed solid geometry, for example.

Next Generation of Digital Factory Planning

A new simplifier function creates minimal envelope bodies. Details such as energy chains or special section tubes are replaced by envelopes, which after simplification, contain a fraction of the original amount of data. The automatic process, which is very quick even when simplifying large amounts of data, reduces the elements of typical assemblies by up to 95 percent.

Formats like DGN for Microstation or JT and STEP allow the transfer to the common visualization systems.

The simplification enables significant compression of the CAD models; therefore, large CAD assemblies such as robot cells or conveying systems are simplified in a very short time and can be handled after conversion in the factory planning software.

Adaptation of the Assembly Structure for the Simulation

With 3D_Evolution CAD, assembly structures can easily be converted into a functional product structure, which are necessary for the simulation. With a few clicks, the user disassembles or “flattens” the original assembly structure in order to merge the parts of the simplified model in such a way that subassemblies and bodies that belong together in the simulation are restructured in a new, functional orientated assembly structure.