Multiaxis Machining Gives Shops Competitive Advantage

With simultaneous 4- and 5-axis machining capabilities, the Mastercam Multiaxis add-on puts basic and advanced machining strategies into the user’s hands. A ‘near miss tolerance’ setting lets the machinist determine how close the cutter can come to the part.

Posted: March 27, 2020

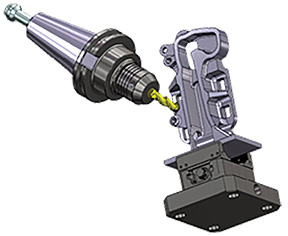

Multiaxis machining can dramatically increase a shop’s competitiveness, which is why Mastercam (Tolland, CT) created Mastercam Multiaxis, an add-on for Mastercam Mill 3D, Router 3D, Mill-Turn, and Mastercam for SOLIDWORKS. Simultaneous 4- and 5-axis machining capability for Mastercam improves productivity, and Mastercam Multiaxis offers a wide range of multiaxis machining strategies, both basic and advanced. These toolpaths are also useful for advanced control of 3-axis machines.

Cut Patterns guide the tool along specified paths. These patterns can be simple 2D and 3D wireframe, solid primitives, or complex multisurface grids. Mastercam’s Multiaxis machining has many toolpath types to govern the cut pattern.

Mastercam’s Tool Axis Control allows orientation of the tool’s center axis to be manipulated as it follows the cut pattern. Users have complete and dynamic control over the tool axis, lead/lag, entry/exit, and tilt, which simplifies even the most difficult multiaxis jobs. Full entry and exit control allow users to determine exactly where and how the cutter enters and leaves the part. An automatic point generator adds greater precision, as well as advanced gouge checking and a 5-axis safe zone around the part to ensure safe cuts in even the most complex operations.

When programming 5-axis parts, it is often necessary to come very close to the part or fixture with the cutter, arbor, or the holder. Mastercam provides “near miss tolerance” fields so users can specify how close they’re willing to get with any part of the tool – and how to avoid those situations.

Mastercam’s Blade Expert Add-On simplifies the toolpath creation process for any multibladed parts, including fans, propellers, impellers, turbines, marine screws, and more. Blade Expert is a very powerful and easy-to-use custom application, designed to generate efficient, smooth, and gouge-free toolpaths for these complex bladed parts.

Mastercam’s Port Expert Add-On creates accurate, efficient engine cylinder head porting toolpaths on port surface or solid data. The Port Expert toolpaths use 3-axis machining as far into the port as possible, and then convert automatically to 5-axis motion with minimum tilt. This avoids fishtails or inefficient reverse moves, and smoothly transitions where the toolpaths meet at the middle of the port.

Included in Mastercam Multiaxis are two innovative machining strategies: Dynamic Motion extends tool life with proprietary toolpath strategies that maximize material removal rate and reduce cycle times, and Accelerated Finishing takes advantage of innovative profile tools and processes aimed at greater efficiency and higher machining productivity.