Industry 4.0 Quality Control Tool for Small Manufacturers

Data analysis isn’t just for large companies. Argolytics’ Trendable software is an easy, cost-effective way to collect and analyze measurement data that can be used to improve product quality and throughput by refining manufacturing processes.

Posted: March 27, 2020

As a sales representative for a statistical software company, Tamela Serensits heard the same complaints over and over again from frustrated manufacturing quality managers: Finance and operations get mega budgets while the quality team pieces together reports from generic spreadsheets and handwritten notes. Budget-friendly, easy-to-use quality software solutions were nearly nonexistent.

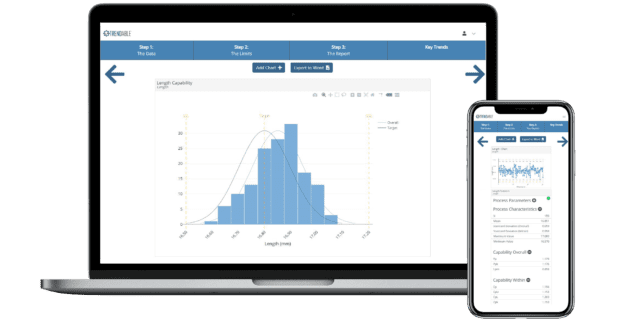

Recognizing the hole in the market, she founded Argolytics LLC. The company’s first product is cloud-based quality control reporting software as a service (SaaS) called Trendable. After users upload data and select tolerances, the platform automatically generates reports that include control charts and capability histograms and plots two key pieces of information – process capability index (CPK) and process performance index (PPK) – that enable people without a statistics background to easily spot long-trend historical patterns in data.

Industry 4.0 for Small Manufacturers

Many small manufacturers can’t afford the sensors, robots, and other high-tech gadgets required to implement Industry 4.0 automation. Serensits’ goal is to provide tools that leverage the power of data analytics without upending their entire business model or production floor.

Data collection is the biggest hurdle for any manufacturing operation wanting to analyze production data. Most smaller facilities and a surprising number of large manufacturers record inspection and measurement information on paper. Even if someone can be drafted into transcribing notes into a computer program, plant managers who wear the quality-control hat have little time to crunch numbers and study spreadsheets.

As a result, meaningful analysis isn’t impossible. However, everyone has a powerful data collection tool in their pocket all the time: their smartphone.

Trendable facilitates analysis of data gathered by a smartphone. The software preselects the most common output for quality reports so a non-statistician doesn’t have to fiddle around with confusing settings. Several features, such as drawing tolerance limits directly on control charts, show when parts go out of spec, track capability statistics over time to alert users when CPK approaches 1.33, and save product tolerances so they don’t have to manually re-entered every time.

Keeping Data Safe and Secure

Cloud storage doesn’t make sense if a plant has invested in onsite servers, databases, and back-ups. Argolytics responds to cybersecurity concerns in two ways.

First, the platform doesn’t save data that’s been uploaded. As soon as the report analysis is created, Trendable clears the cache and is ready for the next raw data upload. Only tolerances are stored for easy analysis of future data.

Second, because the raw data isn’t stored, Trendable has a convenient “Export to Microsoft Word” function for all reports.

The first steps on the road to Industry 4.0 don’t have to upend an organization. Simple tools to collect data from the shop floor, a straightforward analysis package for visualizing improvements, and a safe place to store it all are key to getting started.