Compact, Affordable, Easy-To-Operate Press Brake

With functions such as choice of tool clamp and back gauge systems and a closed O-frame design that provides space for applications along the entire bending length, the Xpress press brake from Bystronic provides an impressive price-to-performance ratio.

Posted: March 3, 2020

Simple to program and operate and featuring a closed O-frame design that guarantees high machine rigidity and provides ample space for applications along the entire bending length, the Xpress press brake from Bystronic (Hoffman Estates, IL) provides concentrated bending technology at an attractive price level.

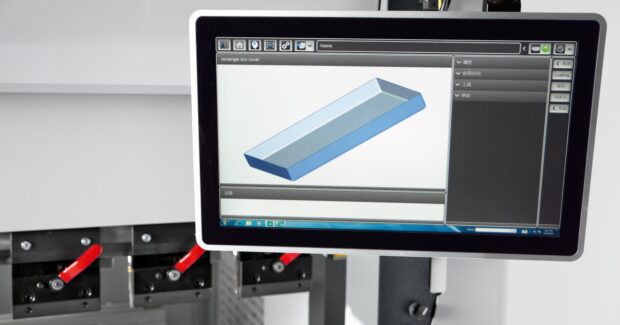

Bysoft 7 software solutions integrate the machine seamlessly into any production environment and enable users to quickly and easily design parts and create bending programs.

ByVision Bending control interface uses a 22-in HD touchscreen and comprehensive database of material bend angles and bend allowances to guide inexperienced operators step by step through the process of programming bending sequences, factoring in material thickness and bending angle to determine the ideal process and suggest suitable tools. The control console has a convenient foot switch.

Profiles can be imported or drawn directly on the screen and then automatically converted to a program. Off-line programming is also possible to avoid interrupting production.

Optional Plant Manager creates and schedules bending programs according to due dates and common tool usage to reduce press brake setup times and maximize utilization.

The machine comes with an open platform communications (OPC) unified architecture (UA) interface that enables machine-to-machine communication and real-time data analysis. Optional ByCockpit software accessible by web-enabled desktops, notebooks, tablets and smartphones monitors overall equipment effectiveness (OEE).

Xpress is available in two models with capacities of 50 tons and 160 tons with powered 4-axis back gauge that, depending on the combination, enables processing of anything from simple angles to complex parts. CNC-controlled wedge-style crowning is available on the Xpress 160.

Bystronic Inc., 2200 W. Central Road, Hoffman Estates, IL 60192, 800-247-3332, [email protected], www.bystronicusa.com.