Calculate Total Weld Cost from Fabrication Shop Data

The updated ESAB Quick Weld Productivity Analyzer tool enables fast report generation and editing. Among its improvements, the calculator provides more filler metal for the North American market.

Posted: March 27, 2020

ESAB Welding & Cutting Products (Annapolis Junction, MD) has updated its Quick Weld Productivity Analyzer (QWPA), an easy-to-use calculator for total weld cost analysis that allows users to generate a PDF report. The PDF includes a QR Code users can scan with their mobile phone that takes them back to their original calculation and input variables; users can then adjust the variables to create alternative calculations and generate a new PDF report. (Click here to try the calculator tool.)

The updated calculator includes more filler metal selections for the North American market. Globally, improved links from the QWPA only present filler metals and welding equipment that are available in the country of origin.

“The updated QWPA interface improves the user experience, while the ability to retrieve and edit calculations saves time and eliminates the hassle of re-entering variables,” says ESAB Global Value Added Engineering Manager Dick Skarin.

ESAB’s Value Added Engineering team developed the QWPA so fabricators can make decisions based on factual data collected at their shop. The online tool is a subset of the comprehensive assessment tools offered by ESAB to help customers increase their overall productivity. The QWPA produces calculations for:

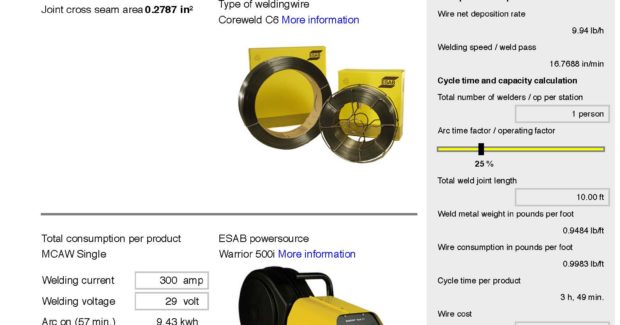

- Net deposition rate and welding speed per pass after selecting weld process and inputting data, (wire/electrode type, diameter, parameters, joint configuration, joint cross seam area, joint length, number of passes).

- Weld operation time calculation. A sliding scale for arc-on time/operating factor calculates weld metal weight in pounds per foot, cycle time per product and energy consumption.

- Total production cost per foot weld or cost per product based on production costs for consumables, energy and labor cost.