Easy Scheduling, Monitoring with CAD/CAM Software Package

The Bysoft 7 software package enables users to quickly and easily design custom parts and input existing drawing and models for editing and processing.

Posted: February 3, 2020

High-performance software is fundamental to modern sheet metal processing. BySoft 7 from Bystronic (Elgin, IL) is an easy to use robust CAD/CAM software package that supports both 2D and 3D CAD and provides the user with an extensive array of process scheduling and monitoring functions, and is easy to operate.

“BySoft 7 is a completely new generation of design and manufacturing software, with a range of new functions that offer a host of possibilities,” says Bystronic President Bob St. Aubin. “We market BySoft 7 with the slogan ‘Make it easy’ and users will find that it delivers fully on this promise.”

BySoft 7 incorporates the latest version of SolidWorks, one the industry’s most popular and respected 2D and 3D CAD packages. Users can quickly and easily design custom parts, and input existing drawing and models for editing and processing. In addition, actual production costs can be determined through an embedded cost calculator.

On the CAM side, BySoft 7 introduces a variety of innovations that improve and simplify the manufacturing process. Operators have the ability to choose either spread or compressed nesting. Spread nesting increases the distance between nested parts for improved process reliability, while compressed nesting minimizes the safety distance to increase the number of parts per sheet and minimize wasted material. Among the extensive list of other innovative features are optimized common cut, pre-piercing of selected contours, and automatic scanning.

BySoft 7 lives up to its ‘Make it easy’ claim in two ways:

First, BySoft 7 employs a highly intuitively structure that enables first-time users to begin working with the software quickly and easily.

Secondly, BySoft 7 simplifies processes within the factory with advanced capabilities for nesting parts, creating cutting plans, generating bending programs, simulating bending sequences, and more.

All operations take place automatically, on the basis of highly reliable data. Optimal cutting plans and bending programs can be generated at the push of a button, with the correct cutting technology automatically set and the bending process is automatically simulated and monitored.

BySoft 7 consists of four modules: BySoft Flat, BySoft Bend, BySoft Tube, and Plant Manager. Plant Manager is a unique operational tool that both plans and monitors manufacturing processes, including all laser and waterjet cutting operations. Moreover, it compiles all relevant machine and production data and makes it continuously available to the operator, providing maximum transparency for both sheet and tube processing.

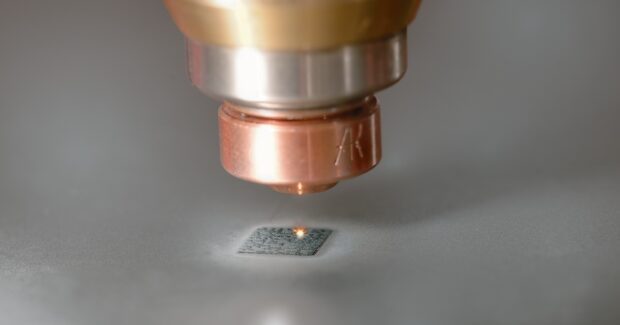

PartID Option

PartID is an option in BySoft 7. The identification code is generated with BySoft 7 and laser-engraved onto the part. At the press brake, the part is subsequently registered by a scanner unit and the desired bending program can be located automatically. Furthermore, parts marked with PartID provide an excellent means of part traceability.

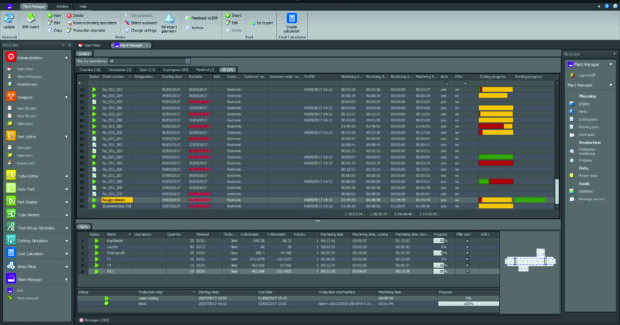

Plant Manager

Plant Manager from Bystronic (Elgin, IL) is a tool for fact-based planning and monitoring of all cutting and bending operations creating maximum transparency and efficiency in your sheet processing.

Each ERP system is subdivided into individual work cycles in the production chain. One of these cycles is the general planning of cutting and bending processes. Here, the Plant Manager assesses and refines the planning automatically. In this way, individual steps and time are saved, costs are reduced, and error sources are eliminated.

Orders and CAD data are automatically processed independent of any programmer intervention, eliminating the time required for cutting plan preparation and feedback to the production planning system. Furthermore, the Plant Manager initiates and monitors parts production and provides you with comprehensive statistical data.

All relevant production and machine data become fully transparent, providing managers critical decision-making data including load balancing of each machine, the order volume and its status, as well as the expected completion and due dates.

The Plant Manager ensures efficient resource management that also takes maintenance periods into account during planning. The user friendly graphical interface makes it easy to quickly locate the required production information. Since Plant Manager regularly exchanges information between the customer’s production planning system (ERP/MRP) and the cutting machines simultaneously, the information provided always represents the most current production data.

Benefits include:

- Manufacture parts more quickly, at a lower cost and with less effort

- Processes run more reliably because manual entries are no longer necessary and machines are regularly maintained

- A complete overview is provided of your production and the condition of your machine

- Data received can further increase your production efficiency

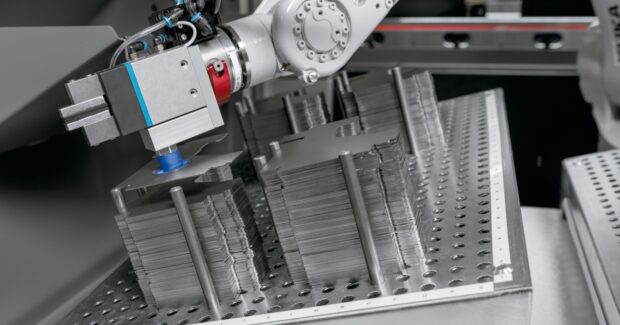

Robot Manager

Robot Manager is Bystronic’s (Elgin, IL) software solution for programming of bending robots that form a part of bending automation. Users control and simulate the robotics that are integrated into the bending automation solutions.

- 3D user interface creates and simulates the required automation steps offline.

- Automation steps include automated bending procedures, feeding in parts to be bent, and stacking the completed parts.

- Integrated assistance and testing functions facilitate the efficient and simple creation of programs.