Sandvik Updates CoroBore 825 Tool

Silent Tools dampening technology and lighter, shorter head enhance performance.

Posted: January 17, 2020

Sandvik Coromant’s (Fairlawn, NJ) CoroBore 825 can be adjusted radially to cover a wide range of diameters with one tool and, when used with Coromant Capto spindle or EH (exchangeable head) interfaces, gives manufacturers even more flexibility. Most recently, the company has dimensioned the tool’s dampers to suit every adapter size in the assortment. In addition to increasing productivity by substantially increasing cutting data, this Silent Tools technology elevates process security where vibration issues are frequently encountered.

Covering diameters from 0.748 in to 6.575 in (19 mm to 167 mm), the CoroBore 825 is suitable for all fine-boring applications. The head is now aluminum instead of steel and has been shortened so the damper comes closer to the cutting edge, further enhancing process stability.

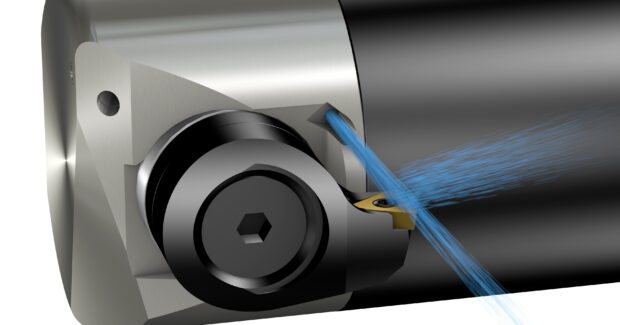

Internal channels that deliver coolant directly to the cutting edge also contribute to improved surface finish, higher penetration rates, and greater process security. The next-generation tools provide optimum performance and stability with one standard adaptive item on the machine-tool side to bridge the tool into a steep taper, HSK, or Coromant Capto spindle.

CoroTurn 107 insert carriers for the new tools have entering angles at 92 degrees to 95 degrees. This increases stability by reducing tool assembly deflection, making it possible to approach the bottom of a blind hold without engaging a greater part of the cutting edge. The insert’s screw clamp design ensures stability and unobstructed chip flow while turning. It’s easy to handle, clean, and maintain.

A new assortment of cartridges can be used for back-boring applications. During back boring, the same internal coolant flow to the cutting edge is offered as in conventional boring.

For easier ordering, the tool, adapter, and insert carrier are delivered as a kit with a single product code.

Sandvik Coromant US, 1702 Nevins Road, Fair Lawn, NJ 07410-0428, 201-794-5000, fax: 1-201-794-5157, www.sandvik.coromant.com.