How EDM Technology Is Adapting to the Realities of the Modern Workforce

The difference between a skilled operator and an inexperienced one is night and day. Machine builders are helping manufacturers remain productive and profitable by deploying technologies that close the skills gap between dedicated operators with extensive knowledge of just one process and today’s jack of all trades.

Posted: January 30, 2020

Efficiency is the name of the game in any manufacturing environment. You can draw a direct line between doing on-spec work faster and profitability. There have been great strides on this front in recent years.

Take sinker EDMs, for example. The same cavity that took 10 electrodes to produce in the 1980s took three in the early 2000s and one, maybe two, today (more on how a little later). Because electrodes are typically the biggest cost associated with running these machines, that’s huge.

An equally important factor in manufacturing success is getting the most from your team. And because of the constant tug of war between needing talent and being able find it, your team is changing.

In the past, EDM work was only for very skilled operators. Today, you go into shops and people run a lot of different machines. Being able to go from the mill to the wire EDM and on to a sinker EDM is imperative to staying competitive, especially now that EDM machines have been proven effective for much more than prototyping and one-off parts.

The difference between an experienced and inexperienced operator is night and day. Here are a few ways machine builders are helping close the gap between the dedicated EDM operator and today’s jack of all trades.

Artificial Intelligence

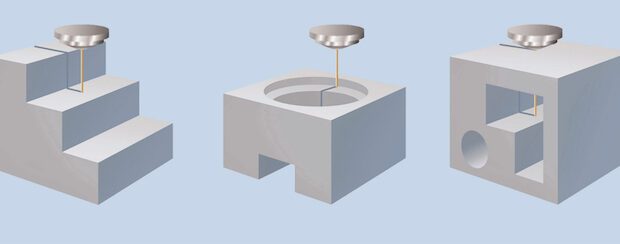

When we talk about a skilled operator, it’s someone who can recognize things like trap areas and program or monitor the operation based on when that will happen. It’s also being able to recognize – mostly by listening – irregularities in frequency, amperage, or instability in the machine.

We like to think of sparks as shovels, throwing up to 20,000/second and digging into the part a little differently each time based on changes in machining environment and materials. Add to that the changing capabilities of modern machinery itself, and no novice operator should be expected to be able to account for everything every time.

The system we’re working on removes much of that pressure. A huge amount of electrical and motor feedback is sent to the control, which can then be deciphered in real time. There are about 20 different parameters in any given sinker machine, and this system can adjust those automatically based on that feedback.

Let’s look at how an artificial intelligence (AI) system can address four of the more frustrating scenarios for sinker EDM operators.

Surface area. Machining always comes down to power and heat. In EDM work, contamination ranks up there as well. The more surface area there is, the faster sparks (power) can be delivered because there’s more area for heat and contamination to spread. AI systems “know” this and can adjust accordingly as the part and electrode erode.

Electrode wear. As with surface area, an AI system can detect changes in the spark field that indicate the electrode wear rate is changing or has gotten to a point where it will negatively affect the part.

Gap contamination. A machine can make parts only as quickly as it can remove contamination. And no matter what shape is being cut, there are going to be different results.

By monitoring the electrical characteristics of the burn, the system can adjust and flush pressure on the fly to control contamination levels and maintain burn consistency and efficiency.

Hydraulic force. Jump cycles are another way of keeping the gap clean. Since keeping liquid between the electrode and part is a must and liquids can’t be compressed, the force they generate can be significant. Its impact on the electrode is often overlooked and difficult to predict, especially as machines can jump faster and faster (some of ours approach 1,000 inches/minute). An AI system can assess the size of the part and electrode along with the speed of the motors to ensure force isn’t so great that it harms the electrode.

Such capabilities have major implications for hiring, training, and retention. While we’re focusing mainly on staffing consequences, using one electrode to machine a cavity that once took 10 and cutting machining time by an estimated 10% to 30% aren’t to be overlooked.

AI Lite on the Wire Side

Wire EDM machines have many more moving parts, which makes full-fledged AI or automation trickier. We are at a place we can call a kind of “AI Lite” in the wire world.

Our version is called PowerMaster. The concept isn’t new, but has evolved dramatically. The operator inputs key parameters, such as material and number of cuts; and once the machine starts burning, it monitors gap conditions in real time and automatically adjusts to get the best performance.

The operator’s burden is reduced further by macro programs embedded directly into the control. These include the most common shapes like keyways or circles. The operator chooses the shape, inputs its dimensions, number of passes, etc., and the machine control generates the program. In about 1 minute an operator can program right at the machine – instead of spending more time at a programming station across the floor – and move on to the next machine.

Validated Processes

Wire EDM systems often deliver where traditional subtractive machining fails. It’s why they’re often used in very delicate, even regulated or standardized work.

Still, introducing extreme heat to a part has risks, and different materials react to different temperatures. When processes are regulated or standardized, factors like discharge current, pulse duration and frequency, wire material, speed, tension, and dielectric flow rates must be precise and consistent.

To help ensure critical processes are followed exactly, machine builders have developed control functions that maintain process consistency and/or virtually eliminate human error. The MC Machinery version of this is standard on the new M800 control and provides the following functions:

- “Check List”

The user creates a custom list of items that must be followed before starting the machine. If an item isn’t checked off, the machine won’t start.

The list can be created as a simple text file on a PC and entered directly in the machine. In an environment such as a validated process, this is a big step in ensuring all steps are followed correctly and not skipped or forgotten due to human error.

- “Protect Mode”

The user can protect or prevent specific operations from being executed. To activate this function, an encrypted flash drive is plugged into one of the machine’s USB ports. This USB comes with the machine and only works for that particular machine. If the protect switch is active, it puts the user into protect mode for the selected functions on the settings menu.

These functions include lockout of the NC program and machining conditions. In addition to locking out any changes, users can also limit or restrict the output of these programs or E-conditions for security purposes. Once selections are complete, the USB can be removed and the machine stays in that mode until changed by authorized personal.

Remote-Controlled EDM Machines

Remote360 is almost a legacy product for us at this point, but, like PowerMaster, it’s constantly evolving. The monitoring system has helped all kinds of shops identify issues with things like uptime and maintenance, and we can even connect to a customer’s machine to diagnose and find a solution to an issue.

We’re also working toward customers being able to connect to our wire EDM machine from anywhere and make adjustments.

Say you receive a notification on your phone that wire is breaking; because the machine is trying to adjust automatically and can’t, an operator will be able to remotely adjust settings. Another example is an operator who forgot to activate an optional stop before leaving for the day to keep a slug from dropping being able to turn that switch on from anywhere.

One way or another, all these advances make life easier on today’s versatile machine operators and have the potential to dramatically improve efficiency. You’d be hard-pressed to identify two factors more important to shop success.

MC Machinery Systems, 85 Northwest Point Blvd., Elk Grove Village, IL 60007, 630-616-5920, www.mcmachinery.com.