Drum-Based Tool-Changer Provides Flexibility in a Small Footprint

The increasing demands placed on cutting technology are leading to an increased need for more advanced machine tools. Engineers in Germany have automated a magazine capable of storing and deploying up to 9,000 tools using PC-based control, EtherCAT, and dynamic motion control.

Posted: January 29, 2020

The increasing demands placed on cutting technology and associated requirements for higher flexibility and productivity are leading to an increased need for more advanced machine tools. A German designer of tool-changing systems and a German control systems integrator responded by developing a space-saving terminal capable of managing up to 9,000 tools.

Founded five decades ago, Wassermann Technology (Eichenzell, Germany) designs tool-changing systems for lathes and milling machines. From concept to commissioning, the family company partners with customers to manufacture complex assemblies.

A customer recently asked Wassermann for a tool changer that can serve as an extension of existing tool magazines or as a central supply magazine for several machine tools. Wassermann enlisted Becker Engineering (Leichlingen, Germany), a control system programmer and machine software developer, for help automating a compact tool terminal with these capabilities.

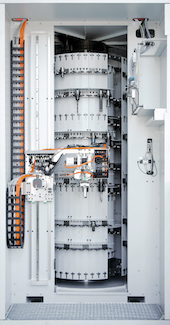

Using PC-based control products from Beckhoff Automation (Savage, MN), they devised a concentrically structured, scalable storage-and-management solution: a rotating outer drum that can be supplemented with two more drums running inside one another around one axis. The nesting-doll design uses space much more efficiently than placing the drums next to each other. The terminal is available in two models – S-Curve for 280 tools and for 570 tools – but could be configured for up to 9,000 tools.

Tools are handled by a linear unit with an integrated tool changer. The latter places the tools in the drums and takes them to a tool buffer or directly to a tool changer on the machine.

Only the diameters of the tools and tool drums are predefined. All other parameters, such as tool lengths, length divisions, number of tools, tool cleaning, tool holders, and RFID tool data acquisition, are configurable by the customer.

Because it has its own tool management, database, sequential control system, and interface to the machine tool, the terminal can operate completely autonomously. In addition, there is software in the tool magazine for external auxiliary handling, interfaces to peripheral devices, and integrated data acquisition for the tooling.

The terminal’s high level of flexibility provides significant cost savings.

“A standard magazine with a wide range of uses provides an excellent price-to-performance ratio,” says Wassermann Technology Managing Director Eberhard Hahl. “Or, if the customer desires, an individual connection to a machine tool can be realized.”

Open and Scalable Control Technology

Such extreme flexibility is largely due to Beckhoff’s open and modular PC-based control software and hardware, which enables machine tools to connect seamlessly to the most diverse control systems available.

PC-based control is just that: an industrial-hardened computer installed in electrical cabinets that runs on the Windows operating system and provides real-time control. Like a home or office computer, it can run third-party software and easily connects to other devices and the cloud.

It’s a much more intuitive, user-friendly platform for configuring machine control than traditional programmable logic controllers (PLCs) that run on proprietary operating systems and require less-flexible programming. In Wassermann’s case, it means the tool database can run on the same platform as the PLC, motion control, and visualization applications, a major advantage for overall system architecture.

Because Beckhoff’s TwinCAT 3 automation software is fully integrated into Microsoft Visual Studio, engineers can program in the object-oriented extensions of International Electrotechnical Commission (IEC) open standard 61131-3 for PLCs, computer science languages, built-in function blocks, and other options in the graphical editor. Wassermann’s application uses TwinCAT NC PTP (network-controlled point to point), which controls multiple axes via a separate I/O connection to each through fieldbuses. Each axis has variables for encoder, drive, and controller.

“PLC and additional high-level language applications can be realized on one universal multitasking platform,” says Becker Engineering Application Software Developer Christoph Neuhaus. “Another advantage is high scalability. Should performance requirements increase, the system enables uncomplicated migration of a control project to more powerful hardware, such as a device equipped with a multicore processor.

“Higher flexibility also means the option to integrate the widest variety of machine tools with the most diverse control platforms. The openness of control is important for this capability. For instance, third-party software can also run on the Beckhoff control hardware, which among other things facilitates access to the tool tables for the individual machine.”

Becker Engineering has worked with PC-based control since 2014, using a variety of Beckhoff products. Getting familiarized was easy.

“Support of common, standardized programming languages significantly simplified programming,” says Neuhaus.

The wide range of communication options via TwinCAT automation device specification (ADS) also made the job easier.

“ADS provides easy access to PLC data from a high-level language application, but it’s just as easy to develop an ADS server in a high-level language you can access conveniently from the PLC,” Neuhaus says. “In this way, reliable transmission of data between the tool magazine and a machine tool can be achieved with little effort to, for example, exchange job numbers or previously evaluated usage data.

“Also, in the case of future developments, necessary updates can be loaded quickly and conveniently. Industry 4.0 solutions can also be realized with the client/server architecture available via ADS communication.”

For Neuhaus, other important aspects of PC-based control include the availability of the current Windows operating systems, the user-friendly software update policy, and the simulation options available without additional license or hardware requirements.

“The complete system can be simulated on your own development PC,” he says. “This means, for example, that you can convert the motion axes to simulation axes or map I/O behavior with hardware using software simulation blocks,” he says.

Convenient and Efficient Motion Control

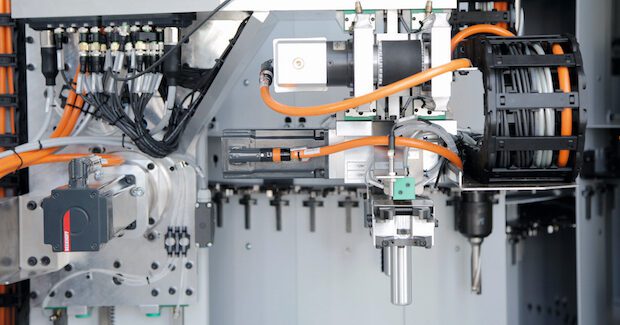

In one tool terminal that Becker recently completed for Wassermann, a CX2030-embedded PC equipped with a 1.5 GHz, dual-core Intel processor operates five axes via five AX5000 servo drives (designed for torque, speed, and position control of suitable asynchronous and synchronous three-phase current motors) and five AM8000 synchronous servomotors. All products are from Beckhoff.

In addition, one rotational axis is provided for each of the two tool drums as well as a vertical axis for reaching the desired drum level, a horizontal axis for reaching into the level, and a rotational axis for a double gripper.

Pneumatic control for the double gripper was an additional automation task. “The tools are transferred from the drum to the outside via the gripper rotation axis,” says Wassermann’s Eberhard Hahl. “This can also be implemented as a telescopic axis to transfer the tool directly to a magazine on the machine without intermediate handling.”

The motion control application was implemented in TwinCAT software with the aid of PLCopen function blocks. PLCopen is an internationally accepted automation standard that puts an “action” into a function block that can be dragged and dropped into the program. Instead of typing out every single letter, number, and symbol manually, engineers can build an application with chunks of prewritten, customizable code.

“Programming motion functions with the associated function blocks was very simple and extremely time-saving,” he says. “Another advantage of Beckhoff’s drive technology is one-cable technology (OCT). It dramatically reduces assembly and material costs and allows the use of smaller cable carrier chains, facilitating more compact designs.”

Beckhoff Automation, 13130 Dakota Ave., Savage, MN 55378, 952-890-0000, fax: 952-890-2888, [email protected], www.beckhoffautomation.com.