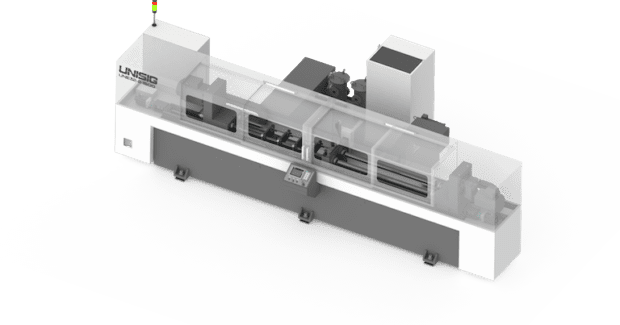

Automation-Ready Gundrilling Machine

Unisig’s feature-rich solution simplifies operation for anyone involved in manufacturing products for the firearms, automotive, medical, energy, defense, and/or aerospace industries.

Posted: January 17, 2020

To give manufacturers the flexibility to grow with future production needs, Unisig (Menomonee Falls, WI) UNE Series gundrilling machines can be designed to be robot-ready so factories can automate doors, safety relays, internal part sensing, and intelligent process integration as budgets and schedules allow.

“A lot of job shops want to automate but lack a timeline to do so,” says CEO Anthony Fettig. “These machines give customers a compact gundrilling solution that’s equipped to grow alongside them.”

All UNE bases are FEA-optimized (finite element analysis) and machined on five sides in single setup for the highest overall precision. This simplifies installation by eliminating the need for foundation work and allows for three-point leveling on machines rated up to 39.4 in (1,000 mm) length.

Several features enhance performance and productivity. The single main spindle servomotor delivers enough horsepower for two-spindle machines. When power is applied in single-spindle mode, however, shops can produce larger-diameter holes, increasing the potential for new business without buying a new machine.

The machines’ intuitive Siemens controls provide a full process picture at a glance on a rich color interface with touchscreen capabilities. Heavy-duty buttons don’t require operators to remove gloves.

The compact frame saves valuable floor space. Each machine can fit near an existing machining center, lathe, or Swiss-style machine for efficient part-processing strategies. Built with quick and easy setup in mind, the machines are also small enough to be relocated when necessary.

Unlike pressure-based coolant systems, the machines’ programmable flow-based coolant-delivery system provides the right amount of coolant to the tool’s cutting edge. As a result, the operator can confidently predict tool breakage and spend less downtime recovering an interrupted process.

UNE Series machines:

- Three two-spindle models with 0.5 in (12 mm), 0.8 in (20 mm), and 1.26 in (32 mm) hole diameters; larger diameters possible when used in single-spindle mode

- Two single-spindle models with 1 in (25 mm) and 1.57 in (40 mm) hole diameters

- Five rated workpiece designation options between 29.5 in (750 mm) and 118.1 in (3,000 mm)

- Solid-carbide, brazed, and indexable gundrill tools.

Unisig, N58 W14686 Shawn Circle, Menomonee Falls, WI 53051, 262-252-3802, www.unisig.com.