Automatic CNC Machine Tending Keeps Die Caster Globally Competitive

“If it’s repetitive, we want to automate it,” says Ron Marconi, engineering and technology director at an Illinois manufacturer of automotive and consumer products components. Faced with losing business to Mexico, the company deployed two robotic cells to increase productivity. The investment paid for itself in less than a year.

Posted: January 30, 2020

“When we look at a process and how we’re going to price our product, we’re not necessarily going to look at labor costs,” says Mike Higgins, sales and marketing director at RCM Industries (Franklin Park, IL). “We’re going to look at labor cost against whether the process can be automated. We’re always asking, ‘What is that investment, and does it make sense?’”

More often than not, the answer is yes.

One example was when the manufacturer of die-cast aluminum components found itself competing with low-wage Mexican suppliers on a consumer plumbing product. In its never-ending search to increase productivity without hiring more employees, the company deployed two identical cells, each with one Universal Robots (Ann Arbor, MI) UR10 e-Series cobot that tends two dual-spindle CNC lathes.

Better consistency and reduced staffing requirements produced a payback of just under a year – and the work stayed in Chicago. “We can be at the customer’s facility or they at ours at a moment’s notice, we understood their product, we had no language barrier, and with the automation we brought consistency and sustainability to the process,” says Higgins.

Employees Move to Higher-Value Roles

“Fifty microns was needed for the very high-precision application,” says Cameron Friend, automation specialist at FPE Automation (Elk Grove Village, IL). “We recommended that cobot because of the increased repeatability and its force-torque sensing capability.”

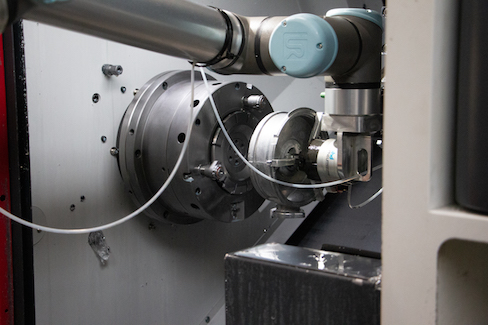

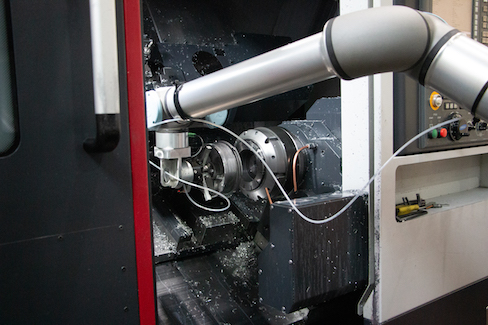

In one application, operators load parts on a table and the cobots move from station to station, picking up a raw part, putting it in a pre-fixture to align it correctly, placing it on the first chuck and then the second chuck, and finally dropping the completed parts onto a conveyor belt to return to the operator. The integrated force-torque sensing allows the cobot to search for the correct position on the chucks and self-align. The cobot can also detect if a part is out of shape and rejects parts that don’t load correctly.

When they were manually loading machines, operators often juggled multiple tasks, such as checking parts and bringing parts in and out of the cell. Even though they could load the machines fairly quickly, they could also be inconsistent.

“A robot does the same motion every time at exactly the same time, so we immediately saw about a 15% increase in throughput consistency,” says Engineering and Technology Director Rob Marconi.

While the cobot works, operators freely enter the cell to perform other tasks. The ability to deploy without safety fencing after performing an initial risk assessment is a key advantage over traditional robots. “The cobot issues an error if it doesn’t load successfully,” says Marconi. “The operator can go into the cell, remove the part, and start up the cycle again without having to open up any safety caging and lock and tag-out the cell.”

No caging also means supervisors can adjust machines while they’re operating. “The dimensions we’re working with require repeated checking and making adjustments in the process,” says Marconi. “We can continue running and allow the supervisor to make those adjustments.”

The deployment dramatically decreased the need for operators. RCM typically ran three shifts with three operators running machines on each shift. Now one employee manages all operations in each shift, reducing staffing requirements by six employees in that cell.

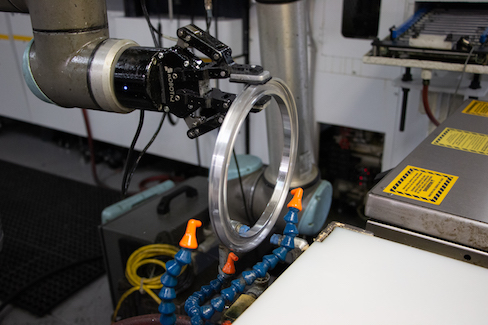

Another application has a cobot picking up metal rings from a lathe tended by a cartesian robot. The cobot puts the parts in a wash tank to wash off lubricants, then circulates the parts in front of a blower to dry them before placing the finished part on drums.

That process used to require one operator per shift. Now the cell runs in the off-shifts with just the cobot. The first-shift operator checks all the parts that come off the second and third shifts, reducing staffing by another two people.

“Staffing is very tough in an urban area like ours,” says Higgins. “Manufacturers are fighting for skilled employees. We need to look at all times where we can automate, especially in repetitive tasks. It’s become a necessity to us to remain globally competitive.”

Programming Experience Not Required

Founded in 1990, RCM is also parent company to four International Automotive Task Force (IATF) 16949:2019-certified high-pressure aluminum die-casting facilities that also provide CNC machining and various secondary operations.

Marconi has no background in robot programming and wanted to keep RCM’s robotics experts focused on the die-casting side of the business, where large, traditional industrial robots in cages pour molten metal into molds. Therefore, ease of programming was a key factor in his decision-making process.

He downloaded the PolyScope simulation software from Universal Robots and created the entire program structure before the cobot arrived. Then he downloaded the program to the cobot and taught it the waypoints onsite using its teach pendant.

RCM Industries chose a PHD three-jaw Pneu-Connect gripper from the online UR+ showroom. The gripper is UR+-certified, which means that it is plug-and-play ready for integration. “All the air valves are built in, all the wiring completed, and any coding necessary to integrate with the cobot already done,” says Marconi. “We plugged a wire into the cobot, installed the software directly into its teach pendant, and were ready to go.”

In fact, he says, “we had an intern come in with no robot experience whatsoever, learn the programming very easily, and work with it throughout the summer to speed up the cycle, to get it to keep up with the machine.”

Fast ROI Justifies Future Plans

Having one robot tend two CNC machines greatly improved return on investment by greatly increasing the existing workforce’s productivity. Not having to hire more employees keeps a lid on employee benefit costs, but RCM also found cost savings related to power requirements. The cobots run on standard 110V electricity and require minimal maintenance, so there’s no need for fully certified automation engineers.

“These cobots are so easily redeployed,” says Marconi. “As our line expands, we plan to move them to different areas and get better throughput from those cells without having to re-do any kind of caging or wiring.” Traditional industrial robots are rarely redeployed because of the downtime related to moving bulky safety caging.

“We had to drive cost out without reducing our value,” says Higgins. “By deploying employees to other departments and other services, we were able to gain revenue and gain capacity.”

FPE Automation, 110 Gordon St., Elk Grove Village, IL 60007, 847-364-7455, www.fpeautomation.com.

RCM Industries, 3021 Cullerton Drive, Franklin Park, IL 60131, 847-455-1950, www.rcmindustries.com.

Universal Robots USA, 5430 Data Court, Suite 300, Ann Arbor, MI 48108-8944, 844-462-6268, www.universal-robots.com.