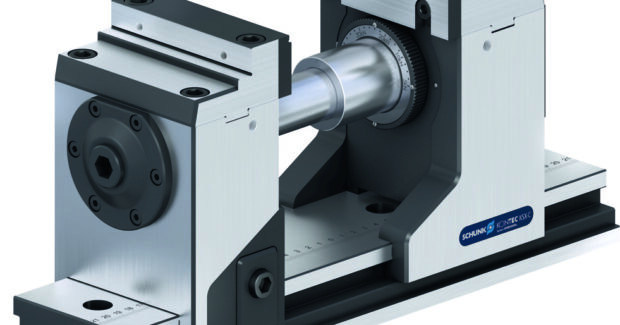

Adjustable-Center 5-Axis Vise

Schunk’s Kontec KSX-C power-assisted vise with continuously variable force adjustment ensures a secure hold event with minimal clamping surfaces. Fully encased spindle, drawbar extensions, and large jaw range enable the vise to adapt quickly and easily to any new requirement.

Posted: January 29, 2020

The drive and adjustment mechanism on Schunk’s (Morrisville, NC) Kontec KSX-C power-amplified vise are fully encapsulated to keep chips, dirt, and coolant from 5-axis machining centers from getting in and compromising operation. The easy-to-clean design avoids chip accumulation, so the machine integrates into modular systems for highly efficient workpiece clamping.

Steady power ensures a secure hold even with minimal clamping surfaces. Forces can be adjusted without tools between 4 kN and 40 kN, and are measured directly on the workpiece. With 160-degree quick-clamping, workpieces are clamped within seconds in a vibration-resistant manner at high repeat accuracy. When clamping by tension, the bending load at the base body is minimized.

The clamping pins of the Vero-S quick-change pallet system can be used to mount the base of the body without an adapter plate. Combined with the quick-change pallet system, the vise can be exchanged on the machine table within seconds.

The jaws can be moved by a laser-etched ruler. The jaw guidance system and clamping mechanism’s arrangement provide a rigid and stable setup, creating ideal conditions for machining the second side.

The vise comes in four body lengths (330 mm, 430 mm, 500 mm, and 630 mm) and two heights (174 mm and 125 mm). It can be equipped with standard, aluminum, or special 5-axis top jaws; pendulum plate; or the company’s other standard chuck jaws.

Schunk, 211 Kitty Hawk Drive, Morrisville, NC 27560, 919-572-2705, [email protected], www.schunk.com.