Upskilling Your Workforce

Retraining strategies for a robotically automated world.

Posted: December 18, 2019

Amid the greatest robotic expansion in history, manufacturers are zeroing in on the fact that cultivating a strong human workforce is as important to harnessing productivity gains and future growth as automating.

A host of dull, dirty, and dangerous manual jobs are now cost-effectively performed by highly intuitive and easily programmable robots, creating safer and more-productive environments for their human coworkers. However, this growing population of interconnected robots, conveyors, and sensors takes a certain level of know-how to operate and manage.

According to the McKinsey Global Institute, a think tank that studies the world’s evolving economy, 14% of workers may have to switch occupations due to digitization, automation, and artificial intelligence (AI). The last such switch happened when the United States moved from an agricultural- to a manufacturing-based economy. That transition happened over decades, giving manufacturers plenty of time to replace retiring employees with employees equipped with the skills to drive growth. This time, change is happening too fast for attrition to resolve skills gaps.

As a result, manufacturers must find ways to redeploy midcareer, middle-age employees. In particular, 62% of executives from diverse industries say retraining employees to work with robots is a top priority over the next three years. To do that, they’re investing in training and creating roadmaps for grooming their future workforce.

If your company’s considering automation, the idea of spending valuable time educating employees while spending large amounts of capital on new equipment can seem overwhelming. However, satisfactory return on investment is more achievable when a comprehensive plan for implementation and training is well-conceived and -executed from the top down.

Just as you must develop a strategic plan for automation, you must also be seen helping develop a roadmap for upskilling employees. Visible involvement by top management minimizes pushback and disengagement by bolstering employee morale.

CREATIVE REDEPLOYMENT

Incorporating robots into manufacturing processes opens the door to new, specialized jobs in areas like quality assurance, robot maintenance, and technical support. Instead of letting employees go, train them for value-added responsibilities in line with their skill set.

Manufacturers that are upskilling in this way report the most innovative redeployment strategies yield the most successful transitions.

For example, early automation adapters converted welders into quality inspectors; moved extroverted employees into sales support positions; and created new positions, such as a robotic workcell “champion” who’s responsible for programming and optimizing utilization.

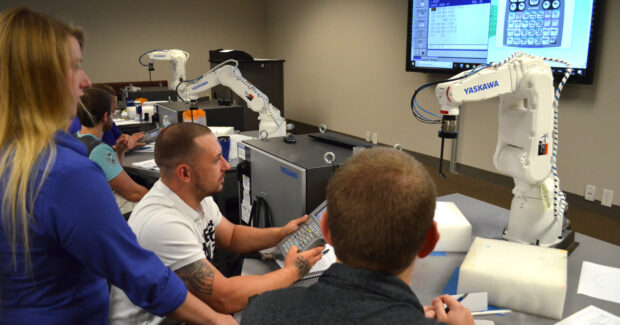

Understanding that insufficient training hinders operational momentum, robot suppliers are working with customers and educational institutions to overcome the challenge of mismatched skills with various training options:

Accreditation

The International Association for Continuing Education and Training (IACET) ensures providers deliver high-quality instruction by requiring them to attain accreditation. Yaskawa Academy, for example, offers 75 courses in application-specific classrooms and state-of-the-art welding labs at training facilities throughout the Americas. Manufacturing employees can also earn continuing education units (CEUs) for robotic courses completed.

Remote Training

A convenient teaching method where a certified instructor from a robot supplier travels to a customer’s facility, providing on-site training that teaches employees how to run and optimize the equipment they’ll use during production.

Microcredentialing

Some manufacturers are working with robot suppliers, like Yaskawa, and educational institutions, such as the RAMTEC program at Tri-Rivers Career Center in Marion, Ohio, and Intelitek, an educational consultant in Derry, N.H., to develop holistic teaching modules that combine Industry 4.0 technologies and processes with usable soft skills.

This plug-and-play approach mixes hands-on, online, and classroom instruction. Upon completion, employees earn “digital badges” for each subset of knowledge learned. Less time-consuming than other methods, blended learning solutions empower employers to customize training that creates a talent pipeline capable of supporting production initiatives.

FORM STRATEGIC PARTNERSHIPS

Every manufacturer is different, and what works well for one organization may not be the best solution for another. You may experience little pushback about learning new skills, but some manufacturers may have to incentivize employees throughout the retraining process to prime them for success.

Either way, I can’t stress enough how important it is to work closely with your robot supplier’s training department. Similarly, you may have to consult a local junior college or technical school to develop a blended training solution that comprehensively addresses your company’s unique technological interoperability and soft skill challenges.

Whether you take a traditional route or customize your approach to redeployment and upskilling, empowering employees to collaborate with advanced robotic technology will enhance your company’s profitability and competitiveness.