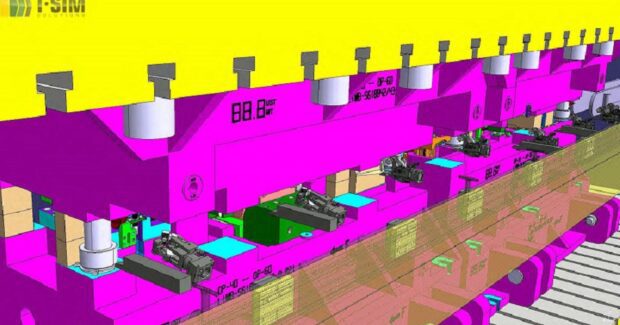

Transfer Press Optimization Service

To help press rooms save time and money Die Cad Group uses T-Sim Transfer Press Simulation software to identify crashes, clearance issues and inefficient transfer system curves prior to any machining of the dies.

Posted: December 4, 2019

The Transfer Press Optimization service offered by Die Cad Group, Inc. (Grand Rapids, MI) builds upon their investment and expertise in T-Sim Transfer Press Simulation software to provide key insights into the transfer die process by identifying crashes, clearance issues and inefficient transfer system curves prior to any machining of the dies, helping press rooms save considerable time and money. Die Cad can also simulate and optimize existing tools for shops to increase capacity in current press operations. “Troubleshooting in the virtual world has many benefits,” said Mary Nicholson, the president of Die Cad. “Not only does it ensure the die is designed and machined correctly, but we are often able to achieve 20 percent productivity gains for our customers through this optimization service.” T-Sim software can analyze incoming part files, fix clash and clearance violations, identify required tool design changes and make adjustments to achieve the highest spm without having to go through physical trial and error on the stamping floor. This applies to servo, mechanical and hydraulic presses, regardless of manufacturer.

Die Cad Group, Inc., 3258 Clear Vista Court NE, Grand Rapids, MI 49525-9477, 616-365-2454, Fax: 616-365-1135, www.toolingtechgroup.com/transfer-simulation.