Smart Workhorse for Laser Cutting, Drilling and Welding Large Parts

The advanced controls and spacious gantry configuration of the five-axis LASERDYNE 890 fiber laser system from Prima Power Laserdyne helps set-up large, complex parts faster for more efficient high-value part processing.

Posted: December 2, 2019

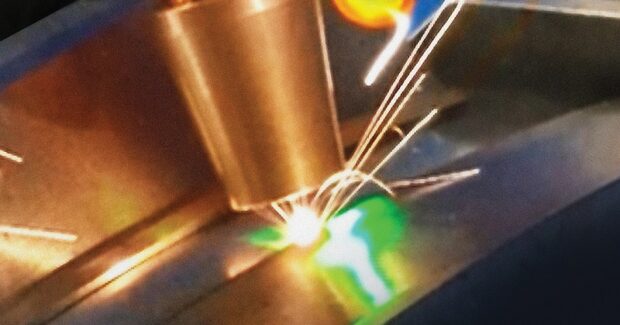

The all-new LASERDYNE® 890 multi-axis fiber laser processing system from Prima Power Laserdyne (Champlin, MN) includes a powerful and efficient fiber laser, the latest highly flexible BeamDirector®, and the S94P control loaded with a full portfolio of Smart Techniques™ operating capabilities. With all of these enhancements and a large 96 in x 72 in x 36 in (2,440 mm x 1,830 mm x 400 mm) work envelope for the X, Y, and Z axes – along with the latest BeamDirector and a complete flexible five-axis work envelope – this system is designed for the most challenging large part welding, drilling and cutting processes. Its spacious gantry design configuration has proven useful in fixturing large and complex parts, allowing for faster and more efficient high-value part set-up and laser processing. With outstanding performance and efficiency, these fiber lasers provide consistent pulse power and energy stability. The Quasi Continuous Wave (QCW) fiber laser delivers maximum peak power equal to 10X that of average power. The S94P controller delivers precise and controlled pulses for consistent and reliable manufacturing processing.

Fiber lasers are more efficient and provide significant cost savings over CO2 and Nd:YAG lasers, i.e., migrating to a fiber laser source eliminates the need for helium gas requirement and lowers the operating cost. The latest generation of BeamDirector technology provides rotary and tilt (fourth and fifth) axes of laser beam motion. Rotary (C-axis) motion is 900 deg about the vertical axis, while tilt (D-axis) travel is ±150 deg about the horizontal axis. The BeamDirector features a direct drive design, optical encoders for high accuracy (± 15 arc-second) and repeatable, high assist-gas pressure and flow, and adjustable mirrors for easy and accurate beam alignment. The high capacity direct drive design eliminates gears and belts for higher accuracy, allowing greater travel and reach over zero offset style wrists. The S94P control includes smart solutions for welding, drilling and cutting of clean, accurately produced parts in a broad range of standard or specialty materials including the latest high temperature and exotic metals. The S94P control includes the following capabilities:

- Automatic Focus Control™ for capacitive part sensing (uncoated metals) creating unlimited “R” axis correction with speed and unmatched sensitivity.

- Optical Focus Control™ (OFC2) (patented) for sensing and mapping of thermal barrier (ceramic) coated surfaces.

- CylPerf™ and ShapeSoft™ graphical programming utilities for producing patterns of cylindrical and shaped holes.

- PresSure™ for control of assist gas pressure from within a laser processing program.

- Adaptive hole size control is the single best method of producing the highest quality laser drilled holes, ensuring hole size and critical flow requirements with minimal operator involvement.

- SPC Data Acquisition™ monitors and records key processing data used to create each part and records the data in a permanent record.

- MTConnect™ provides real-time streaming of the process parameters in support of Industry 4.0 operations.

The LASERDYNE 890 also incorporates “Smart Techniques,” an expanding suite of proprietary capabilities that are standard features of the S94P control that include:

- SmartShield™ provides protection against excessive oxidation in the weld area while also protecting the beam delivery optics with regular, clean shop compressed air.

- SmartPierce™ minimizes spatter and reduces time for piercing in cutting and drilling processes.

- SmartRamp™ eliminates the depression at the end of laser welds.

A true workhorse, the LASERDYNE 890 incorporates a rigid base with heavy-duty steel weldment construction, a robust motion system with precision machined surfaces and reliable motion controls. This system provides the newest and widest range of laser processing capabilities to meet and exceed complex part laser processing requirements.

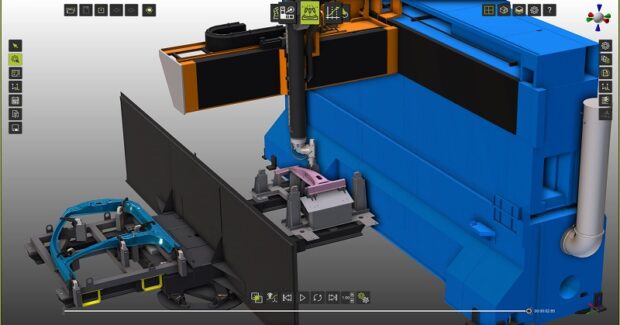

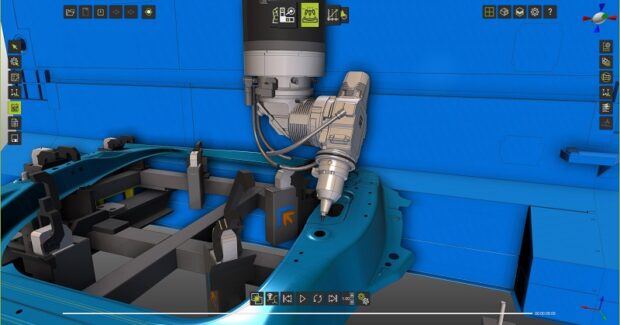

Prima Power also distributes FASTSUITE Prima Power Edition software developed by CENIT AG (Stuttgart, Germany) with their 3D Prima Power laser machines. This software supports the entire offline programming process, from importing CAD files to optimizing the NC program. Programming and simulation are optimally adapted to the laser cutting processes on Prima machines for efficient, intuitive and rule-based programming. Shops benefit from a modern, easy-to-use user interface, an integrated cycle time simulator and simple license management. The software features a very flexible fixture builder for automated definition of prototype fixtures, as well as series fixtures with integrated clamps. The FASTSUITE Prima Power Edition is compatible with any CAD system and open for the support of current machine concepts, such as the use of external axes for component handling.

Prima Power Laserdyne, 8600 109th Avenue North, #400, Champlin, MN 55316, 763-433-3700, Fax: 763-433-3701, [email protected], www.primapowerlaserdyne.com.