Next Steps in Progressive Die Design

VISI 2020.1 mold and die software from Hexagon improves progressive die design processes and enhances part unfolding, deburring, reverse and graphics functionality.

Posted: December 5, 2019

VISI 2020.1 mold and die software from Hexagon Manufacturing Intelligence (North Kingstown, RI) improves progressive die design processes and enhances the Reverse module. Upgrades to new part unfolding technology provide the ability to work directly on the original solid model, support blanking functionality and manage parts with non-linear bends. Sheet metal part recognition provides an improved graphical representation of the part, analyzed by identifying bends, planar faces and features. Different face types can be set to be considered for the blanking process. The part unfolding technology allows linear blank unfolding and flange unfolding to be combined into a single functionality. With linear bends, the system will unfold using the linear bend unfolding technology, while flange areas unfold using the FEA unfolding solution. Coining faces can also be unfolded as part of the same process.

The major advantage of the new part unfolding technology is the associativity provided with the original model during the die design process. It allows the original part to be modified and changes to be automatically propagated on the banked part. All of the linked parts can be rebuilt in reference to a modification done to the original part, which is extremely useful because it updates all of the studied parts in a single click and saves major time in the design and modification phase of a progressive die. VISI 2020.1 also provides a direct interface to Stampack Xpress for die simulation.

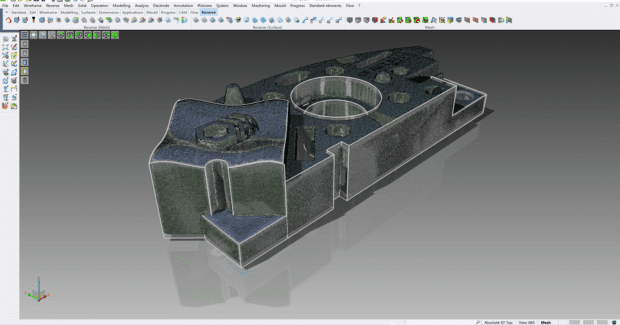

The Reverse module has additional functionalities for both Reverse and Casting processes, including new features to support the scanning to surfaces generation. Features such as radius generation from mesh, plane generation, adapt mesh on boundary, and sectional curves on mesh provide greater benefit for the reverse process from point scanning to solid model generation. A new Best Fit feature aligns a stock model to the final solid model by setting tolerances on different faces. This is extremely useful for the casting market because it allows the cast model to be scanned, achieving a best fit alignment with the final geometry, producing an optimized toolpath with reduced machining time. The stock model can then also be used for machining simulation purposes. The Compare feature provides an improved graphical evaluation of the results and displays distances between the scanned model and the final solid model. These enhancements improve quality to both processes and save time from the scanning to the manufacturing process.

New body-to-mold functionality provides a quick way to define the correct position and orientation of a plastic part on the tool and allow transformation of the model from the ‘car in line’ position to the mold position, and to apply the required shrinkage value. The original position of the model can be restored if modifications are required for the molding of the part. This is extremely useful for the automotive market and other applications, saving time in the mold design process.

Creating CAM operations on any arbitrary part geometry is relatively easy now because parts can be virtually designed, created and produced. But once CAM is finished, one last operation that is not yet automated is usually done manually after machining: Razor sharp burrs occur on all parts with straight edges or non-tangent outer surface topologies. Burrs appear when the tool chips metal off the edge. This unwanted situation can destroy the functionality of the part, be a danger to the worker, and must be removed. A new automatic five-axis deburring function in 2020.1 provides automatic finishing to the machined part’s sharp edges – an important phase of manufacturing parts with no tangent surfaces. It significantly reduces deburring setup time by creating a highly automated toolpath to deburr sharp edges of a workpiece with a spherical tool that is positioned in the bi vector of the automatically detected sharp edges. Automatic tilting and linking is then applied to avoid collisions.

Five-axis Autotilting capabilities include new smoothing options based on a more sophisticated interpolation algorithm that optimizes the contour while keeping the tilt angles in a limited range for more fluent movement of the machine while milling the part. New graphical representations assist in validating the model for manufacturing purposes. Undercut and Accessibility shading also identifies undercut areas during the design and modelling phases, providing the ability to validate a model for manufacturing purposes at an early stage in the design to manufacturing process.

Hexagon Manufacturing Intelligence, 250 Circuit Drive, North Kingstown, RI 02852, 855-443-9638, Fax: 401-886-2727, www.hexagonmi.com.