FULLY INTEGRATED LASER AUTOMATION

Multifunctional system controls production from loading, cutting, sorting, and unloading to finished-parts storage.

Posted: December 24, 2019

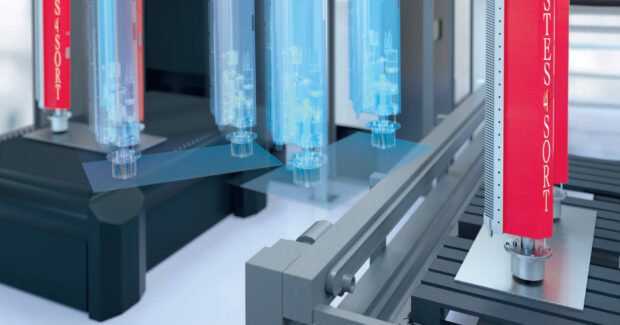

Mitsubishi Electric Corp. (Tokyo) partner MC Machinery Systems (Elk Grove Village, IL) offers an automation system developed by Mitsubishi company ASTES4 (Balerna, Switzerland). Each of the sheet metal laser cutter’s four robotic grippers uses vacuum or magnetic tools in various shapes and sizes to more efficiently sort.

The machine’s control software sorts parts into kits. Different material thicknesses can be kitted on the same pallet. The software automatically optimizes and manages the entire production process without operator interaction. Remote access and a camera system allow for continuous monitoring and intervention if needed.

MC Machinery Systems, 85 N.W. Point Blvd., Elk Grove Village, IL 60007, 630-616-5920, www.mcmachinery.com.