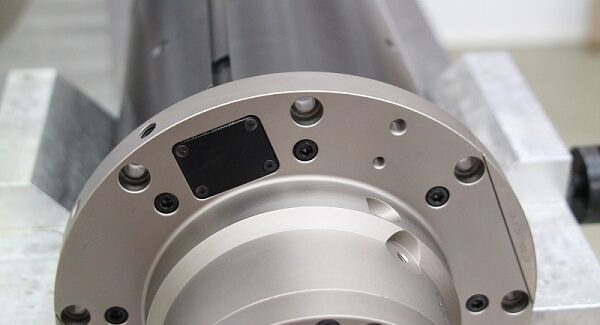

Electro-Spindle Monitors Cutting Processes in Real-Time

The e-SPINDLE from PCI / Absolute Machine Tools integrates sensors and actuators to monitor cutting processes and adjust parameters to optimize tool life and part quality.

Posted: December 9, 2019

The e-SPINDLE from PCI SCEMM, a Tongtai company and partner of Absolute Machine Tools, Inc. (Lorain, OH), is an electro-spindle that integrates sensors and actuators to monitor cutting processes and adjust parameters to optimize tool life and workpiece quality. It can perform real-time monitoring of cutting process variables on toolholders, including force, vibration, and coolant pressure. Or provide ongoing vibration control of adaptive drilling applications. Or for a honing toolholder operation, it can perform integrated measurement of workpiece diameter to permit continual control of abrasive honing tooling. PCI developed e-SPINDLE technology in France in collaboration with the Technical Centre for Mechanical Industry (Cetim) and the Aix-en-Provence campus of the French Arts et Métiers engineering and research graduate school. “This technology is another way our customers can participate fully in smart manufacturing, the IIoT, and Industry 4.0,” said Steve Ortner, the president of Absolute Machine Tools.

Absolute Machine Tools, Inc., 7420 Industrial Parkway, Lorain, OH 44053, 800-852-7825, www.absolutemachine.com.