Automated Adaptive Milling

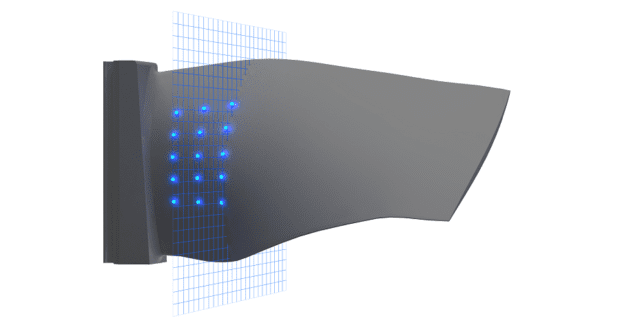

Automated adaptive blade milling from Liechti Engineering measures the workpiece in the machine and CAM software generates and optimizes a tool path that eliminates human error, optimizes productivity and ensures the highest quality result.

Posted: December 9, 2019

To help aerospace manufacturers keep pace with the ever-increasing demand for flawless components, Liechti Engineering, a GF Machining Solutions (Lincolnshire, IL) brand, automated the adaptive milling process to improve efficiency and eliminate human error. While adaptive blade milling itself is not new, this approach to automation changes the way high-value aerospace components are manufactured. With automated adaptive blade milling, the workpiece is measured in the machine and TURBOSOFT computer-aided manufacturing (CAM) software generates and optimizes the tool path which, by eliminating human error, optimizes productivity and ensures the highest quality result. This automated adaptive blade milling system can be fully integrated with a range of flexible manufacturing systems (FMS) to achieve further gains in efficiency.