How to Increase Output for Large Stainless Steel Sheet Surface Polishing

To meet demanding production schedules in a competitive environment, this shop eliminated wasted time, improved utilization, reduced the number of setup sheets and increased their saleable sheets by correcting the grit being used on their custom finishing machine.

Posted: November 22, 2019

Striving to increase output, a large stainless steel sheet manufacturer had a strategy in place to increase the table speed of their three-headed (top heads) wide belt sanding units. However, due to surface finish and mechanical issues they achieved very little success and sought a better solution. Upon first review of their overall process, it was observed that due to the initial setup of the equipment – which they performed according to the machine builder’s instructions – they were processing anywhere from 25 to 32 “break-in” sheets each day. This process was implemented in order for them to run an entire day with the same three wide belts. Their goal was to reduce the abrasive belt cost by using overly aggressive grits in the initial setup (allowing them to “break-in”) and then run an acceptable Ra (roughness average) after that break-in period. Valued at $500 per sheet, this would be a potential loss of sales of up to $16,000 per day. Perhaps at least equally important would be the loss of 32 sheets daily or 160 sheets weekly in overall output – which amounted to nearly a day of production lost each week in current output.

With exceedingly tight production schedules in a competitive environment, few shops can afford to maintain this amount of loss, either financially or by delayed customer orders. Something else had to be done. To increase the output on large stainless steel sheets, a different approach was taken than those recommended by other abrasive suppliers or the machine builder. Based on the Ra range required (no higher than 25 Ra and no lower than 10 Ra), a new process was developed to meet this range much quicker and reduce the number of break-in sheets:

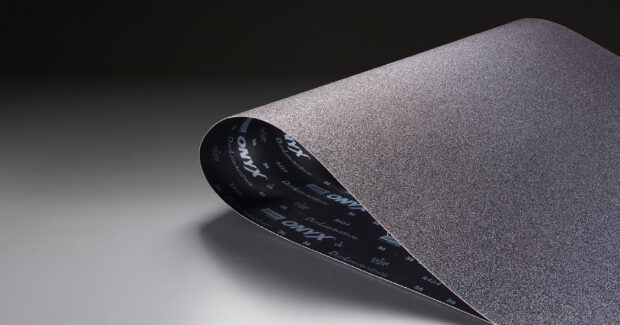

- A 100 grit, X-weight silicon carbide cloth belt was placed on the first head of the sanding units to remove all surface defects (nicks, cut, dings, etc.) without leaving a scratch pattern that is too deep or too wide that would need to be reduced later.

- After the initial rough cut process, heads two and three used paper or cloth X-weight belts with 120 grit silicon carbide grain. Either backing works, but the cloth appeared to provide slightly longer life and sustained a higher head pressure and amperage. The use of these grits, which were a couple steps finer than what was being used previously, allowed the shop to go from 32 break-in sheets down to 12 setup sheets in one run, then down to ten in the next.

This new operation translated into a reduction in waste of at least 20 set-up sheets per day, or an output of $10,000 in additional product. For the week, this generated up to $50,000 in value improvement and substantially increased productivity by eliminating the massive material handling efforts being performed by the operators: In the original process, the sheets also had to be moved from the exit end of the machine back to the start position. The new process increased the opportunity to run beyond what was considered the standard daily production of 200 sheets.

POSING A “LESS THAN OPTIMAL” SCENARIO

Further examining the new process, a less than optimal scenario was reviewed. Production numbers were based on running only three-quarters of a shift each day. For the week, there were seven belt changes vs. the best scenario of having only five changeovers. Using cost numbers of $200 per belt for head one (cloth belt) and $135 each for belts on heads two and three, the changeover cost was $470 per set. Operating a three-quarter shift, the weekly cost was $3,290 as compared to the cost of $2,350 if the set of belts last a full shift. This was an increase in abrasive cost of $940 per week, along with the additional cost of 20 break-in sheets, which was $10,000 for the week. Even this less optimal scenario example realizes a weekly value improvement of $40,000 in stainless steel sheet production with a minimal increase in abrasive costs of $940. This was a net cost value improvement of $39,060 for a normal full week of production on the finished stainless steel sheets. Also, this was possible with no compromise in the overall sheet finish quality and with an acceptable finish achieved much quicker using the finer silicon carbide grit setup vs. using the coarse belt.

The use of the coarser grits showed very little overall value in finish and was certainly not efficient in terms of time and output. By correcting the grit, the manufacturer clearly eliminated wasted time through setup sheet reduction and also improved utilization. Their large custom-made finishing machine is now running saleable sheets vs. re-run sheets. Overall, this new process is a multi-tiered improvement.