Automated Handling of Small to Medium-Sized Parts

Strong, fast and flexible 2200 Series low profile belt conveyors from Dorner are engineered for part transfers to part accumulation, precision part movement, small part handling and positioning, part/package infeed and outfeed, automated and manual assembly.

Posted: November 22, 2019

Strong, fast and flexible 2200 Series low profile belt conveyors from Dorner Manufacturing Corporation (Hartland, WI) are engineered for handling a wide range of small to medium-sized part applications. Their single-piece frame design reduces the overall number of needed stands and comes with a universal T-slot that is compatible with industry-standard hardware for fast and simple attachment of accessories and guiding used for part transfers to part accumulation, precision part movement, small part handling and positioning, part/package infeed and outfeed, automated and manual assembly. A 5/8 in nose bar transfer option with V-guided belt tracking safely transfers parts at speeds of up to 200 fpm for increased productivity. Tool-less fully adjustable guiding provides users with added flexibility to further customize their conveyors to best fit their needs. The 2200 Series End Drive conveyor can be equipped with a universal drive that provides flexibility in design layout and simplifies spare part management with a single part number that covers all speeds, loads and mounting position. Other features of 2200 Series belt conveyors include:

- Widths between 1.75 in to 24 in; lengths between 18 in to 24 ft.

- Load capacity up to 120 lb; belt speeds up to 400 fpm.

- Precise rack and pinion belt tensioning that allows for fast and simple tensioning.

- Sealed-for-life bearings that reduce maintenance.

The 2200 Series Modular Belt conveyor features additional belt options, a sleek open frame design and the universal T-slot that is ideal for metalworking applications. Its ladder-style, open frame design replaces traditional perforated bedplates to allow better airflow through the frame for cooling and water, and for chemical drainage applications. Its sleek, narrow profile can be positioned under machinery and in other tight spaces where other conveyors wouldn’t fit. Its high-speed 0.31 in nose bar transfer option allows for safe and efficient transfers of small parts at speeds up to 175 fpm. This conveyor comes with two styles of plastic chain belting: A micro pitch, general purpose modular belt with a 17-tooth, 1.7 in pitch diameter drive, 1.125 in diameter standard idler and 0.31 in nose bar transfer; or a metalworking modular belt with 1 in or 2 in cleats, a ten-tooth, 1.88 in diameter drive and a 1.125 in diameter standard idler. End drive models are compatible with the universal motor and mounting package that covers all speeds, loads and mounting positions with a single part number. Other features of 2200 Series Modular Belt conveyors include:

- Three drive options: End Drive, Center Drive or an iDrive consolidated motor and control offering.

- Widths between 3 in and 24 in; lengths between 18 in to 30 ft.

- Loads up to 150 lb and speeds up to 250 fpm.

- A ten-year warranty.

- Shipment in five business days.

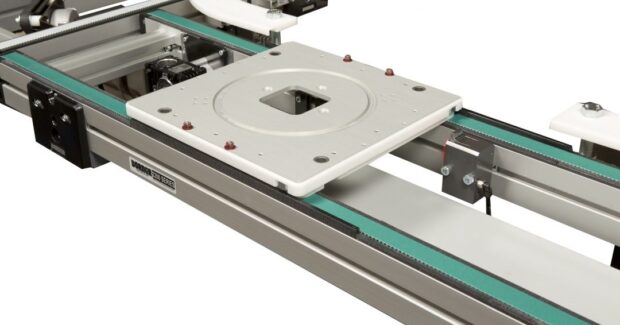

When applications call for precise movement of product, the 2200 Series Precision Move conveyor is engineered for accurate movement of material at specific times, distances and intervals that are critical for components in manufacturing of small to medium-sized parts. Precision Move gives greater product control and accuracy to automated applications, including machine integration, robotic pick-n-place, precision indexing, accurate part positioning, timed conveying, vision inspection and part handling. The timing belt and servo motor combination adds a level of precision capability to the proven 2200 Series platform. Features of this conveyor include reverse V-guide belt tracking along the entire length of the conveyor to provide seamless belt performance without the need for side guides; expanded conveyor sizes and a small 1 in wide conveyor option with tip-up tail for easy belt removal; additional servo motor support with selectable motor manufacture and model numbers, as well as additional gear ratios for enhanced performance. Other features of the Precision Move conveyor include:

- Loads up to 200 lb.

- Heavy load corners, tight turn corners, low-profile lift and locates, elevators.

- 12-tooth T10 profile; positive drive, no slip belting.

- Conveyor lengths: 1.5 ft to 30 ft; conveyor widths between 1 in and 24 in.

- Belt speeds up to 370 fpm.

- Conveyor only repeatability ±.020 in; servo package repeatability ±.040 in.

Easy programming, fast set-up and flexible deployment make all of these 2200 Series ideal for systems that need an infeed and discharge to a robot from Universal Robots USA Inc. (UR; Ann Arbor, MI). Dorner worked with Universal Robots to develop software that allows users to control 2200 Series conveyors using the UR controller. All of these 2200 Series conveyors are a certified UR+ Solution that simplify robot and conveyor integration for a wide variety of automated applications. After customers purchase their UR robot and 2200 Series conveyor, they simply download the UR plug-in, making the integration of these conveyors easier to setup, configure and control. The URCap can be found on the www.dornerconveyors.com/dorner-ursolutions website. Once the program is installed, the conveyors can be added to the control program and the user is able to program the inputs and outputs needed for starting, stopping, speed reference, and status information.

The URCap is designed for both CB series and e-Series controllers. Programming for the variable speed drive should be done using the Frequency Inverter Operating Instructions manual. A robot programming manual will be supplied with the robot or can be found at the www.universal-robots.com website. The UR+ Solution-certified 2200 Series conveyors are compatible with the following robots:

- UR3 Robot: 3 kg payload

- UR5 Robot: 5 kg payload

- UR10 Robot: 10 kg payload

- e-Series Universal Robot bots

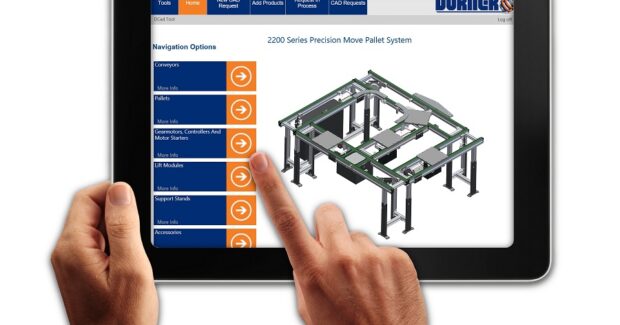

When purchasing a 2200 Series conveyor, a user can engineer a complete conveyor and download a complete 3D CAD assembly model for instant validation of fit with the Dorner DTools online configurator. They receive real-time updates as they design and modify conveyor systems using the 3D Preview function in DTools, a fully interactive, live experience that provides them with more information than ever before. When building their conveyors in DTools, a 3D CAD model is simultaneously developed to match their designs. As the conveyor is modified, the configuration updates to correspond with those changes, giving the customer live updates and rotatable 3D views of their conveyor systems prior to submitting them for quotation. Dorner builds its 2200 Series conveyors to exact customer specifications and ships them within three business days.

Dorner Manufacturing Corporation, 975 Cottonwood Avenue, PO Box 20, Hartland, WI 53029, 262-367-7600, Fax: 262-367-5827, i[email protected], www.dornerconveyors.com.