Silence Is Golden: Versatile Deep Part Marking of Hard Materials

The C-Series Silent Scribe marking system and Sound Abatement System from Columbia Marking Tools quietly marks new types of alloys, steels, high-strength low-alloy steel (HSLA) and different formulations of casting materials that require versatile marking pressure capabilities.

Posted: October 9, 2019

Marking hard materials with a deep mark is vitally important to manufacturers in many industries today. Processes such as painting, plating, heat treating and subsequent machining can make shallow marks disappear, and in a shop floor environment that requires absolute traceability, the right marking process must be applied. Columbia Marking Tools, Inc. (CMT; Chesterfield Township, MI) pioneered enhanced application development of dot-peen marking, low-stress dot-peen marking, impact marking, roll marking, laser marking and now scribe marking. “We study the customer’s process and apply the best marking system for the application to meet the type of mark required, production requirements, noise and safety of the process, and, ultimately, the quality of the mark, which could involve date stamp and shift codes, QC marks, part numbers, traceability marks, UID Compliant and 2D Matrix Square Dot™ codes, company logos, lot numbers, and even trademarks,” said Tom Phipps, the chief executive officer of CMT.

Phipps continued, “Today we are seeing an increased need for deeper marks in new types of alloys, steels, high-strength low-alloy steel (HSLA) and different formulations of casting materials, all of which require versatility in the range of marking pressure capability. But how do we define a deep mark? In some cases, it can be as deep as 0.0310 in. The depth required is what limits the type of marking process. For example, typical laser marking depth is 0.0005 in for any reasonable production rate. Standard dot-peen marking is up to 0.0030 in, but with an air-operated impact marker you can achieve average marking depths of 0.0080 in and with roll marking up to 0.0120 in.” Recently CMT developed a new C-Series of markers that perform both dot-peen and what is called the ‘Silent Scribe’ CNC marking system. They originally patented programmable CNC scribe marking machine technology in 2005, primarily for standard I-Mark™ scribe markers for marking 2D Square Dot matrix codes.

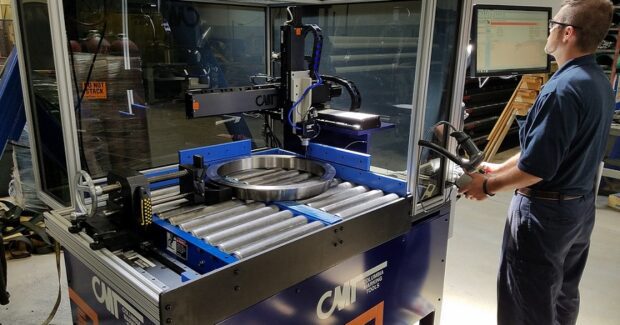

The C-Series marker utilizes an XYZ axis slide arrangement that is driven through precise ballscrews. The scribe head, mounted on a platen that is linked to the slides, uses a diamond stylus to quietly scribe text or graphics into hard or soft surfaces producing fully-formed lines, curves, and 2D matrix codes. The control of the head movement is provided by a programmable controller that interfaces with standard Windows®-based systems combined with the high-power I-Mark marking system to create the marks and codes. Utilizing high-power stylus actuators that operate on relatively low air pressure, the C-Series can produce extra deep marks. The ballscrew and linear bearing axis design permits the user to have either a quiet-running servo motor drive that provides high-speed marking capability up to ten characters per second with 0.005 mm positioning accuracy, or a high-performance stepper motor drive that gives 0.02 mm repeatability at five characters per second.

This machine can operate as a stand-alone or, because of its compact size, can be easily integrated into an automated production system that use robots because the marking head is designed to ‘get-out-of-the-way’. With C-Series component architecture, the individual axis can be customized from 40 mm to 500 mm travel or more, allowing for extreme flexibility.

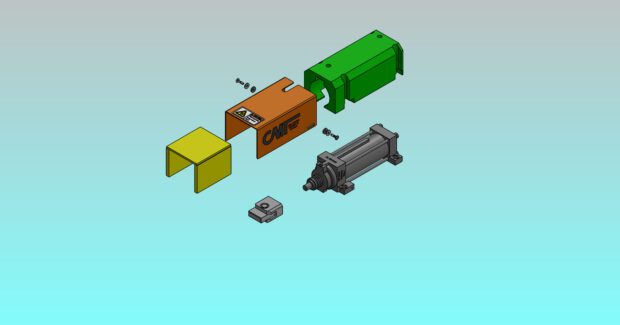

As the industry looks for methods to reduce decibel resonance on manufacturing processes, CMT has recently introduced the SAS (sound abatement system) for use with their patented 8 ton Model 751 and high-powered 12 ton Model 851 Slide-A-Mark double-acting air-operated impact markers for applying impact marks for date stamp and shift codes, QC marks, part numbers, traceability marks, company logos, lot numbers, trademarks and even some staking operations into a wide variety of materials. Over the years, these impact markers have evolved with improved types of alloys, steels, including high-strength low-alloy steel (HSLA) and different formulations of casting materials to provide more versatility in the range of marking pressure capability. CMT now offers four standard solutions to reduce impact noise:

- SAS Marker Slip-On Form Fitting Sleeve

- SAS Ram Sleeve Surround

- SAS Pliable Stamp Holder/Retainer Surround to reduce part resonance

- SAS Turnkey Marking Station with Frame (including all of the above)

The sound abatement design includes a lightweight, high density, flame retardant, plastic sound-absorbing cover for the cylinder assembly and an “add on” optional sound absorbing ram sleeve designed to accommodate various part stamp tooling lengths, depending on the application. SAS can be purchased as a retro-fit package or with the purchase of a new Model 751/851 marker. Retrofitting takes only minutes to install. SAS can be purchased as a complete stamping unit with a machine frame and an optional sound-absorbing, high-mass adjustable telescoping pedestal base for robot cell application. Robot manufacturers can specify a junction box with terminal strip pre-wired to part and motion sensors and actuation air valve to make a faster and cleaner installation. CMT can also provide a manual load/unload station. The Model 751/851 marker is designed with a cylinder body and bolt-mounting pattern to enhance interchangeability. A variety of different keyed air-powered rod and stamp holder styles are available.

The Model 751/851 marker can produce a force range of 1/4 tons to 8 tons. In operation, it utilizes a two-stage impact marking sequence where the marker telescopes out to pre-load the stamp or staking tool against the workpiece, then the cylinder fires an internal hammer generating a consistent impact force that is varied by controlling the actuation air pressure. Fixed internal air passages control the marker’s speed. A typical 2½ in unit cycle is less than one second). The Model 75/851 marker is also offered with optional retracted or dual position sensors for return and advanced position of the cylinder stroke to augment their application with automation. By simply loosening a mini dovetail clamp, the advance position sensor can be adjusted to one inch. Strokes can range from 2½ in to 12 in while the marking pressure remains the same anywhere within the stroke. Slide-A-Marks are powered by factory air and controlled by a standard four-way air valve with a regulator to vary the marking force. It is recommended the mail shop supply to be a ½ in air line with a maximum pressure of 100 psi.

Columbia Marking Tools, Inc., 27430 Luckino, Chesterfield Township, MI 48047, 586-949-8400, Fax: 586-949-8401, [email protected], www.columbiamt.com.